STERN 2 participation on track

Although our Preliminary Design Review (PDR) of the DLR STERN Project is being rescheduled due to the outbreak of the corona virus, all HyEnD members are working hard (and from home) in order to bring the project forward. We think this is a great opportunity to give you an update of the current state of the project.

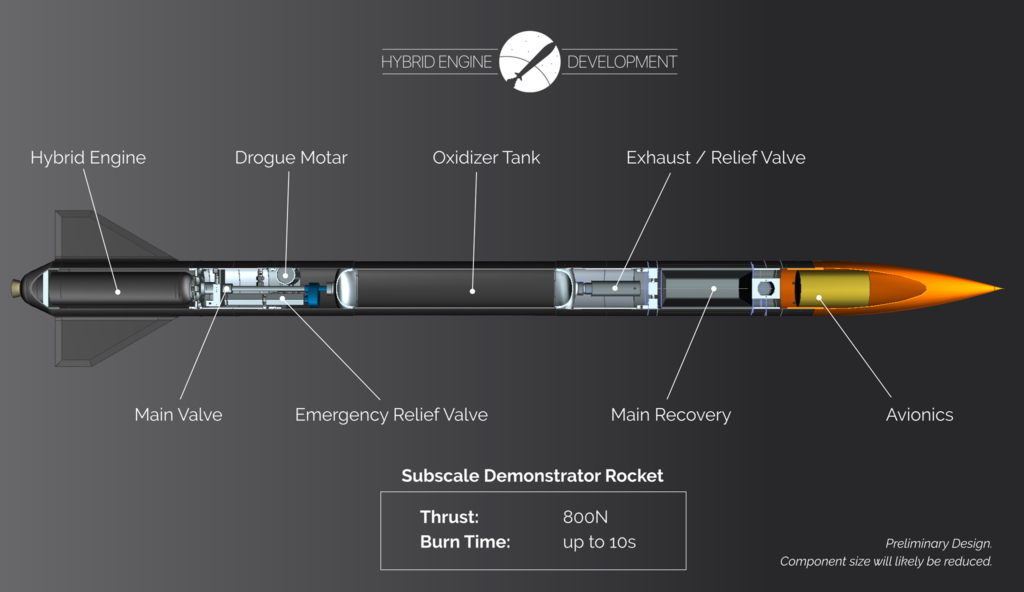

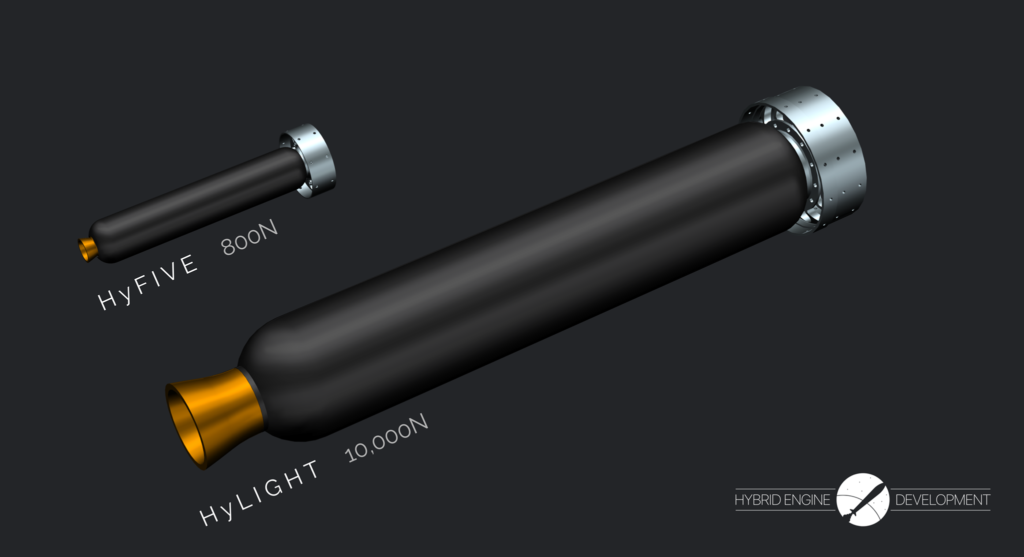

Propelled by its powerful HyLIGHT Hybrid Rocket Engine, our project rocket N2ORTH will fly to an altitude of 20km or higher and will be fully recovered. The engine will provide a nominal thrust of 10kN over an operation time of minimum 15 seconds. It will use a new type of in-house developed polymer-based fuel in combination with nitrous oxide. The whole rocket is designed from the ground up using the experience gained with the previous HEROS rockets. In order to test the different systems of the rocket in advance, we will build a subscale demonstrator rocket which will be launched next year. Currently, HyEnD is focusing its work mainly on this demonstrator. In the following, we will give you an overview of the different systems of the rocket.

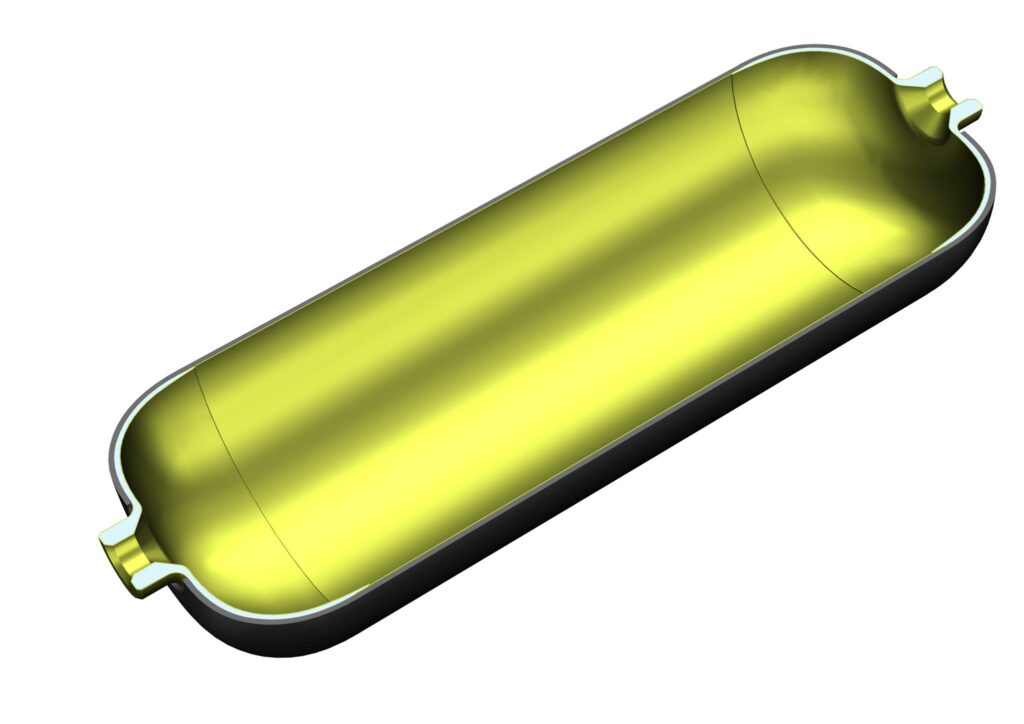

Structure and oxidizer tank:

The structure team evaluates different design approaches for several lightweight rocket structure elements. One of the most challenging parts is the oxidizer tank, which is planned to consist almost entirely of composite materials. Several design and manufacturing approaches are investigated, including designs without the use of an aluminum liner. This is challenging since nitrous oxide usually causes problems in a hydrocarbon-based environment.

Engine:

The propulsion team has already started fuel evaluation tests back in fall 2019 and has built a completely new engine called HyFIVE-1 in order to continue these tests. The first test was scheduled for March 2020 but was canceled due to the corona virus. Currently, the team is working on the design of the demonstrator flight engine, which will use a carbon fiber reinforced plastic (CFRP) combustion chamber hull in order to reduce weight. First design studies for the larger HyLIGHT engine are currently in progress as well.

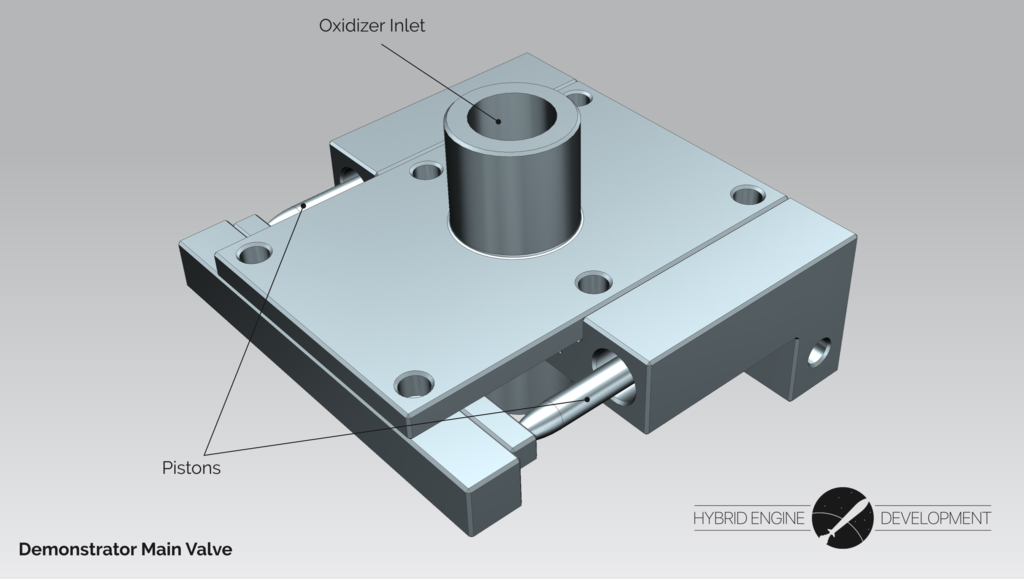

Fluid System:

In the last weeks and months, the fluid system team has developed a simulation model for the self-pressurizing behavior of nitrous oxide inside the tank. This is crucial in order to determine the required tank size and resulting engine performance. Also, three design studies for every valve were carried out, emergency and relief valve prototypes are currently being manufactured. For the main valve, a pyro charged slider valve is considered.

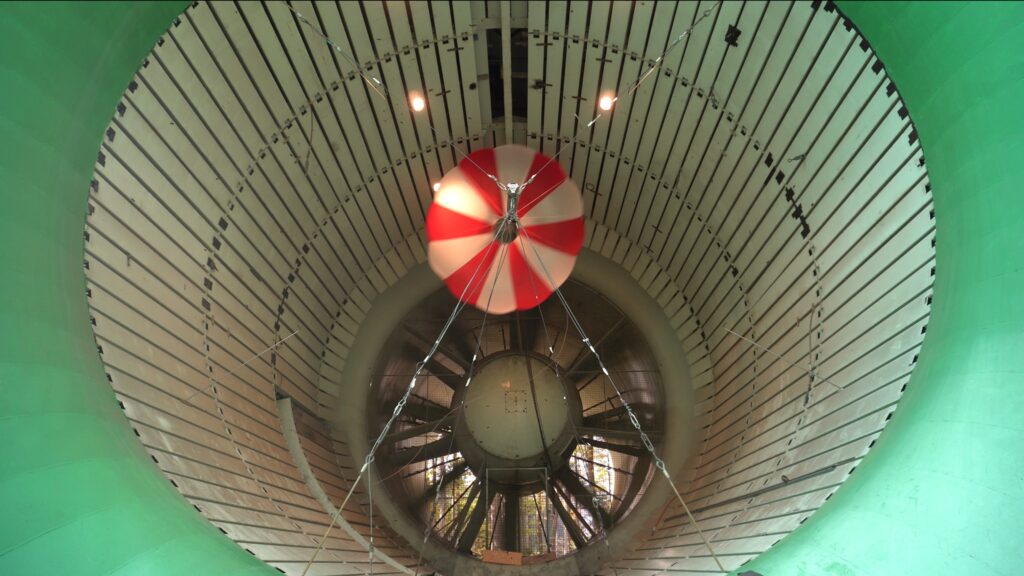

Recovery:

Since the rocket shall be required entirely, the rocket will be equipped with a two-stage parachute recovery system. The recovery team has carried out different concepts and decided that the following mechanism will be used. First, the drogue will be ejected with a motar placed between the oxidizer tank and engine. The main deployment mechanism is located near the top of the rocket. It includes the main chute and a pilot chute. The drogue and pilot chute are deployed using pyrotechnical charges. First tests to verify drag coefficients and shock loads for the demonstrator rocket were already done in October 2019.

Avionics:

The Avionics team is currently focused on developing the individual systems. Choosing the right components to implement in the design is crucial to keep the systems as compact and space efficient as possible. For each systems a schematic containing all the used components as well as the connections in between them are designed.

Ground Support Equipment:

Members of the ground support equipment team are working on a custom launch rail for the demonstrator rocket. For N2ORTH, the MRL in Esrange will be used. Also, different concepts for the arm mechanism (responsible for fueling the rocket) were carried out and it was decided to use a rotating arm. Tasks also include the development of an antenna tracking platform, which will enable a life video feed during flight.