BLAST stands for Biliquid Launch and Space Technology and is our team’s current main project. In its course, we are aiming to develop a sounding rocket which combines several innovative and complex technologies.

Recovery

The BLAST recovery system will be a single chute system. In order to mimic the two-stage behaviour of the traditional drogue-main-combination, we are currently developing a self-made active skirt reefed main parachute. By choosing this approach, we hope to drastically decrease total system mass and volume.

We are planning on using a reefing line to control the opening of the parachute. While this will allow us to move the actuators away from the parachute skirt into the rocket’s hull, it also creates two parallel lines, which have to swivel around the same axis. To avoid any entanglement of the two lines, we are designing a custom hollow swivel which will allow the reefing line to pass through the main line swivel.

Since there is relatively little research in active parachute reefing systems at small scales, we will perform tests to determine the parachute type best suited for our configuration. In early wind tunnel testing, we have already found the traditional round canopy parachute to be very unstable in comparison to other parachute shapes.

There are no concrete plans for ejection and reefing actuation yet. For testing purposes and the upcoming HyDra 3VO launch, where we will fly a two parachute recovery system, we have already developed a mortar ejection system and self-made line cutters for the ejection of the main chute. To decrease the mass of the Blast ejection system, we are looking into other means of deployment.

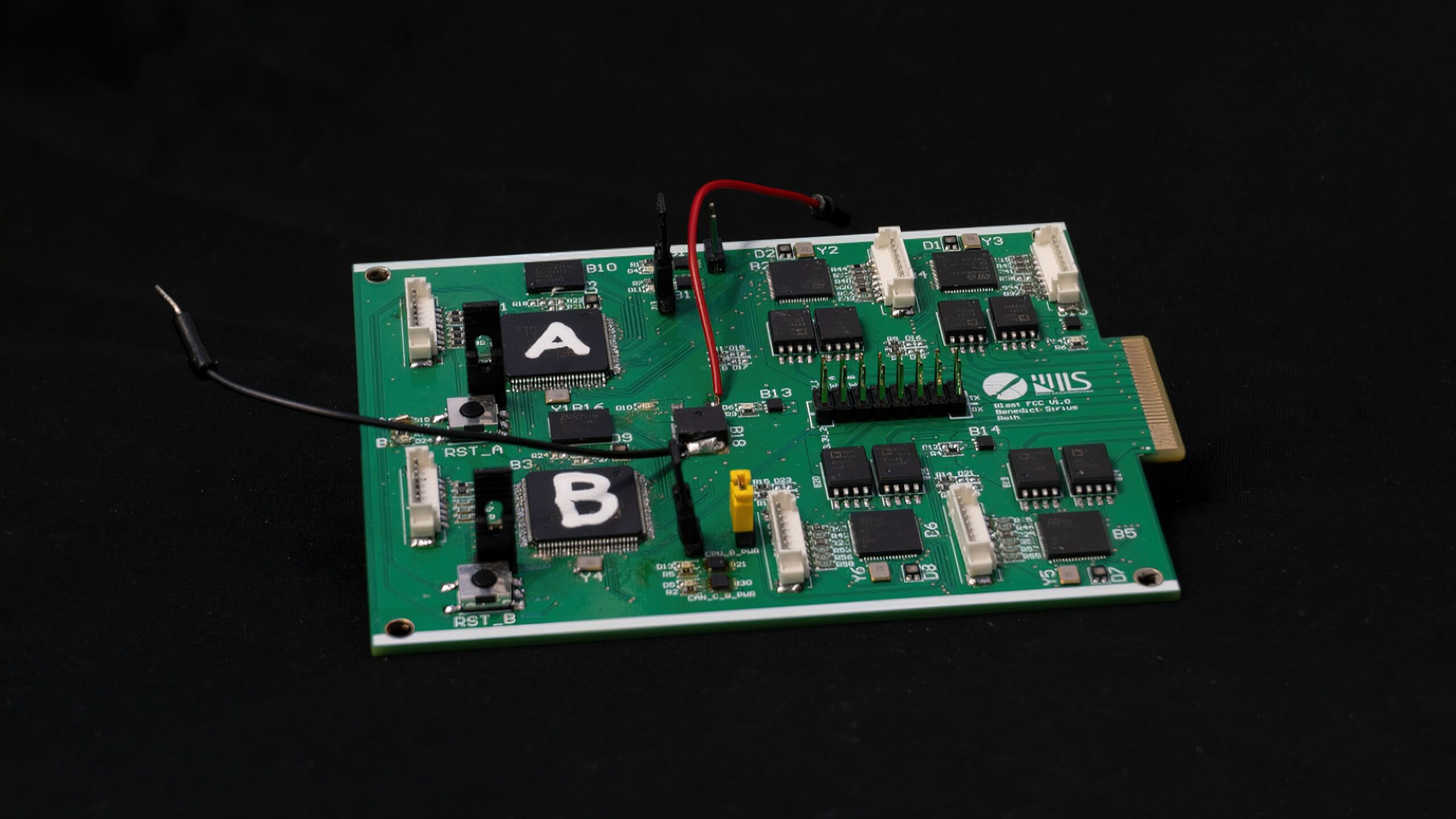

Avionics

The term “avionics” encompasses all electrical systems active during the mission. Our central task is to ensure that the parachutes are deployed at the right time, since this is vital to mission success. In order to ensure its reliability, a redundant system based on a modern microcontroller is developed in-house from the ground up.

Our other tasks include data collection and transmission, as well as the physical structure and power supply which will be needed in order to perform aforementioned central task.

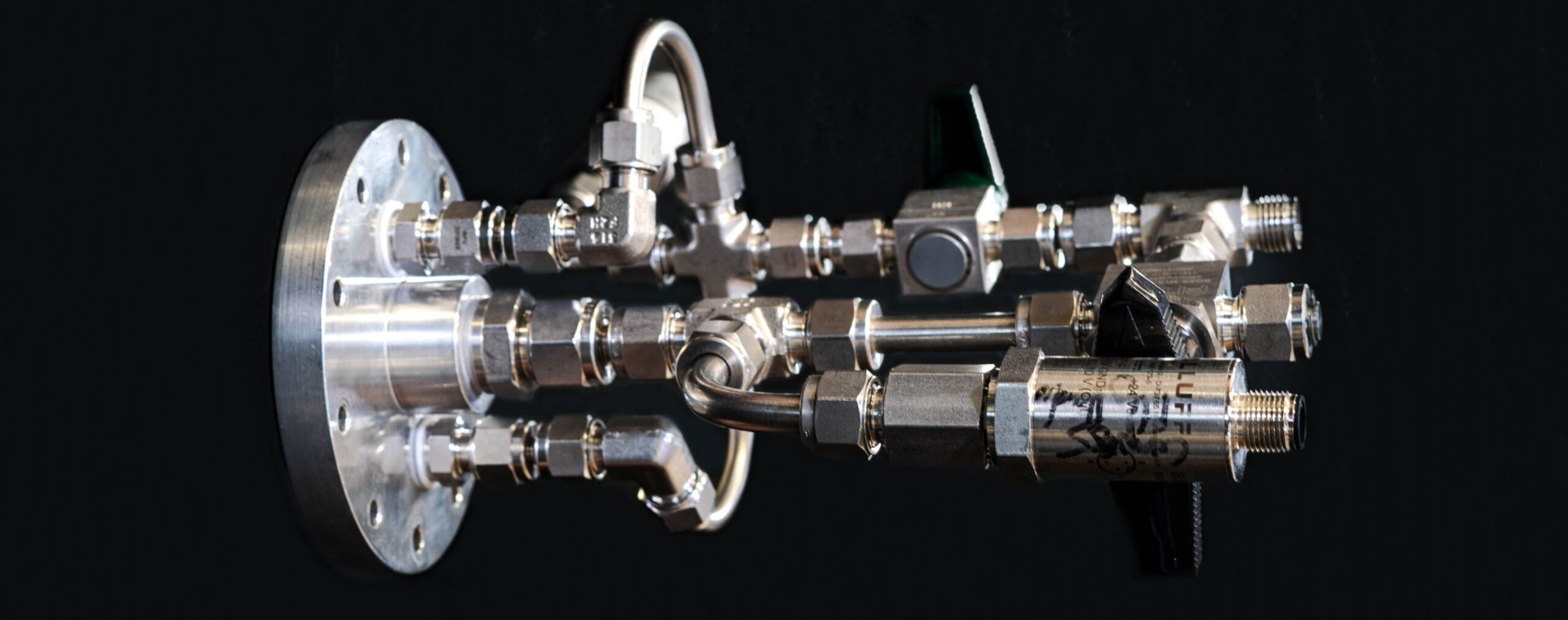

Fluid System

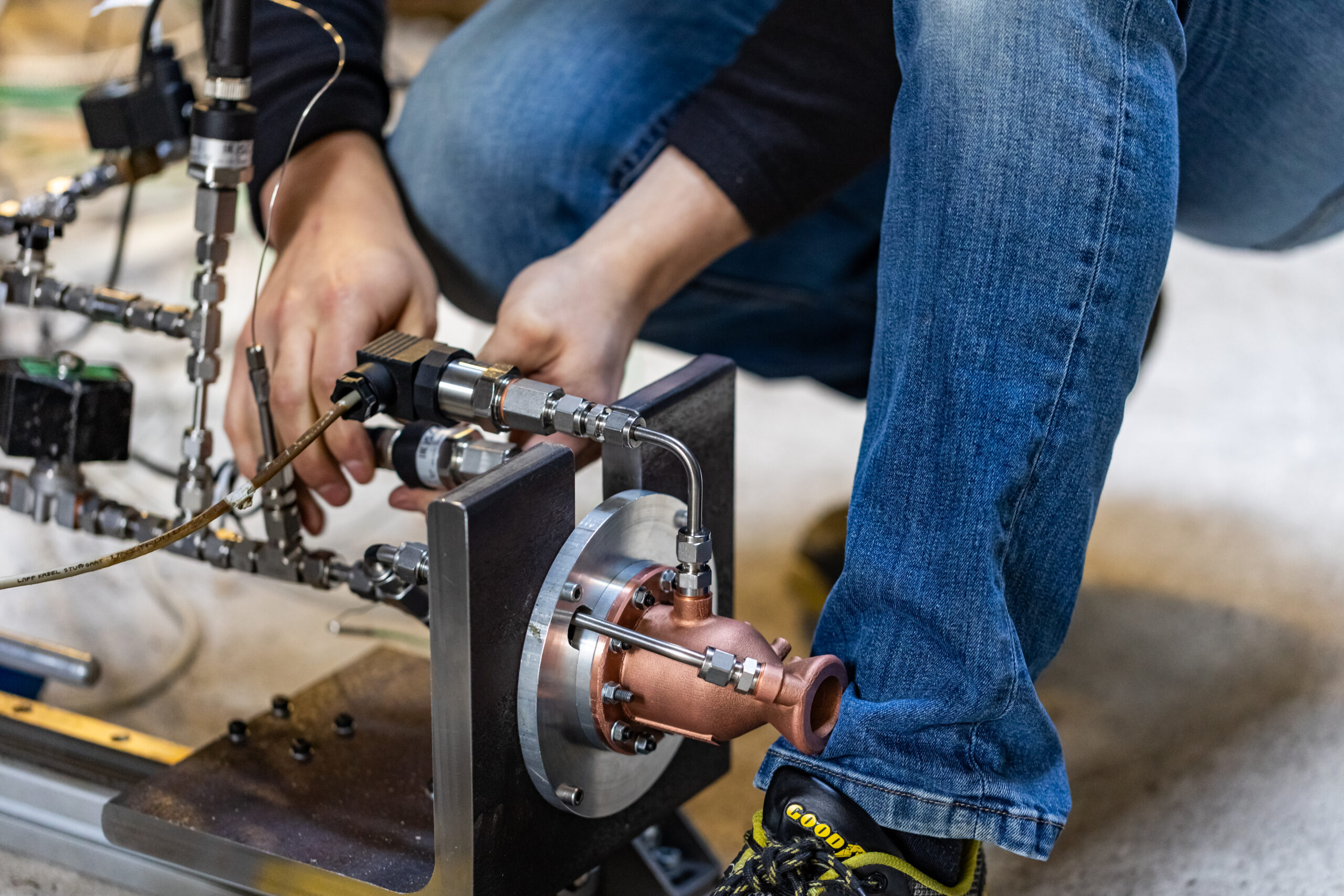

Our fluid system is marked by cutting-edge features, notably the use of a 3D-printed main valve, ensuring weight reduction and a more compact design. Rigorous testing procedures are implemented to guarantee system reliability, validating its performance under diverse flight conditions.

Key achievements include the development of robust depressurization mechanisms, such as self-designed pressure relief and vent valves, ensuring secure and controlled tank evacuation. Collaboration with Ground Support Equipment (GSE) specialists ensures a smooth tanking process, optimizing the integration of the fluid system with ground support infrastructure.

The team’s focus on a highly integrated system prioritizes optimization of weight and volume, resulting in a compact and efficient rocket design. Constant pressure regulation is maintained through mechanical pressure reduction, thus adapting to changing conditions during flight.

Structure

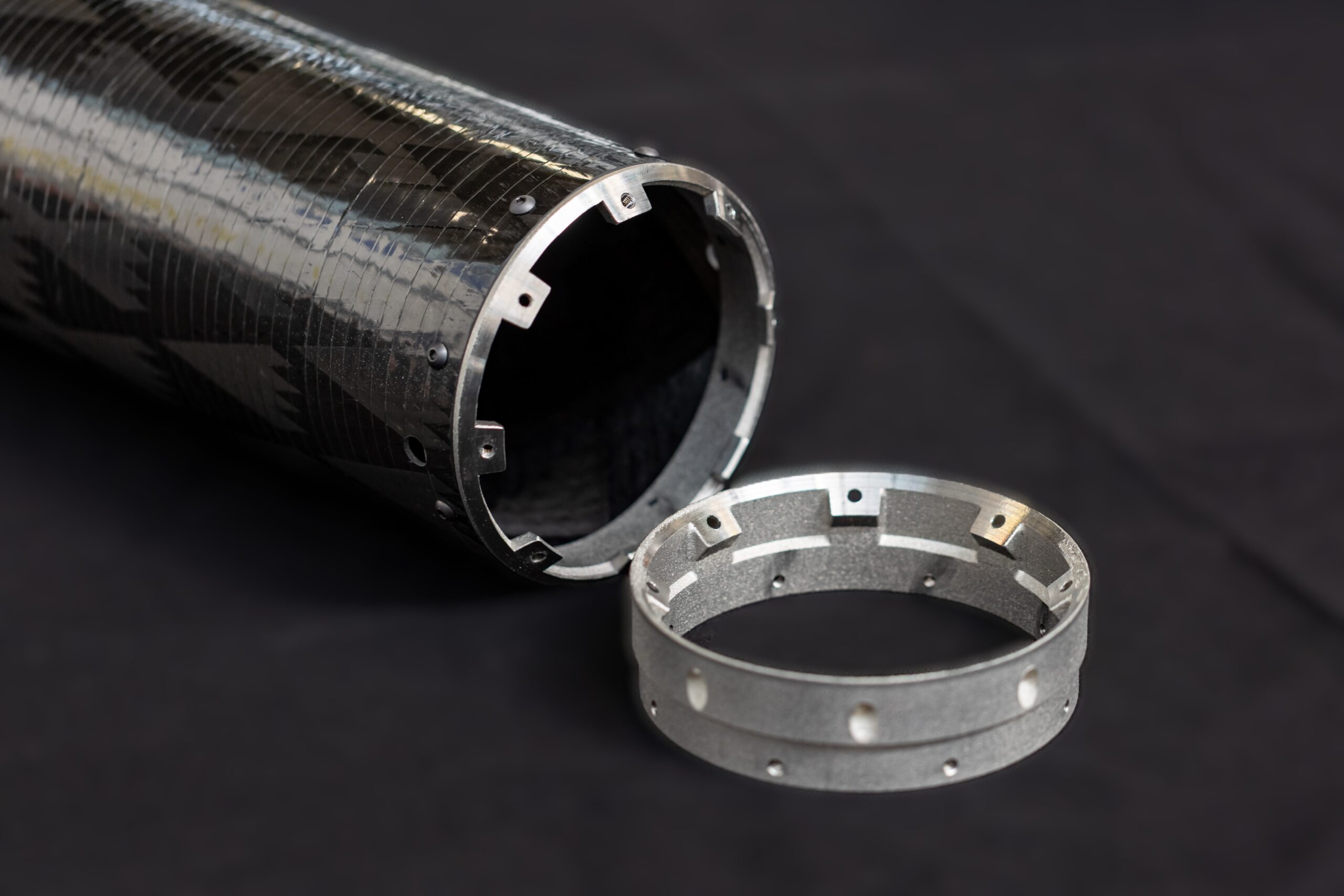

All components will be optimally designed to the flight profile of our rocket and will be verified through mechanical, thermal, and aerodynamic simulations as well as rigorous testing, including load cycle and vibration tests.

To push the light-weight engineering of our rocket to its limits, we will also be using RADAX connectors to join the various parts of our rocket together as this compact connection allows us to reduce the total length of the rocket. While RADAX connectors are conventionally made of metal, one of our members has designed a CFRP RADAX connector for his bachelor’s thesis. Implementing this change of materials will lead to massive overall weight savings.

We are currently developing a linerless CFRP oxidizer tank using an in-house developed epoxy resin matrix which does not react with nitrous oxide. On top of the cheaper manufacturing cost, this Type V pressure vessel will have significant weight reduction compared to an aluminium-liner tank, which was used in our previous rocket and is currently the state-of-the-art in oxidiser tank development.

We have already successfully developed a linerless CFRP fuel tank, which has been pressurized to 120 bar. It will soon be tested to destruction in order to determine its limits. The filament winding machine used to make these pressure vessels as well as the rocket’s exterior hull has been built and perfected by HyEnD’s members and is powered by TANIQWind. TANIQ’s substantial support has enabled HyEnD to take the next steps in fiber-wound lightweight design, compared to our N2ORTH rockets. Owing to the TANIQWind software, reliably reproducible pressure vessels and hull structures can be produced, which is invaluable for research and development on HyEnD’s state-of-the-art lightweight structures.

Further innovations that we wish to realize in the course of this project include retractable rail buttons that will improve the aerodynamics of the rocket’s flight, an integral tank design as well as manufacturing our engine mount from light-weight composite materials.

Propulsion

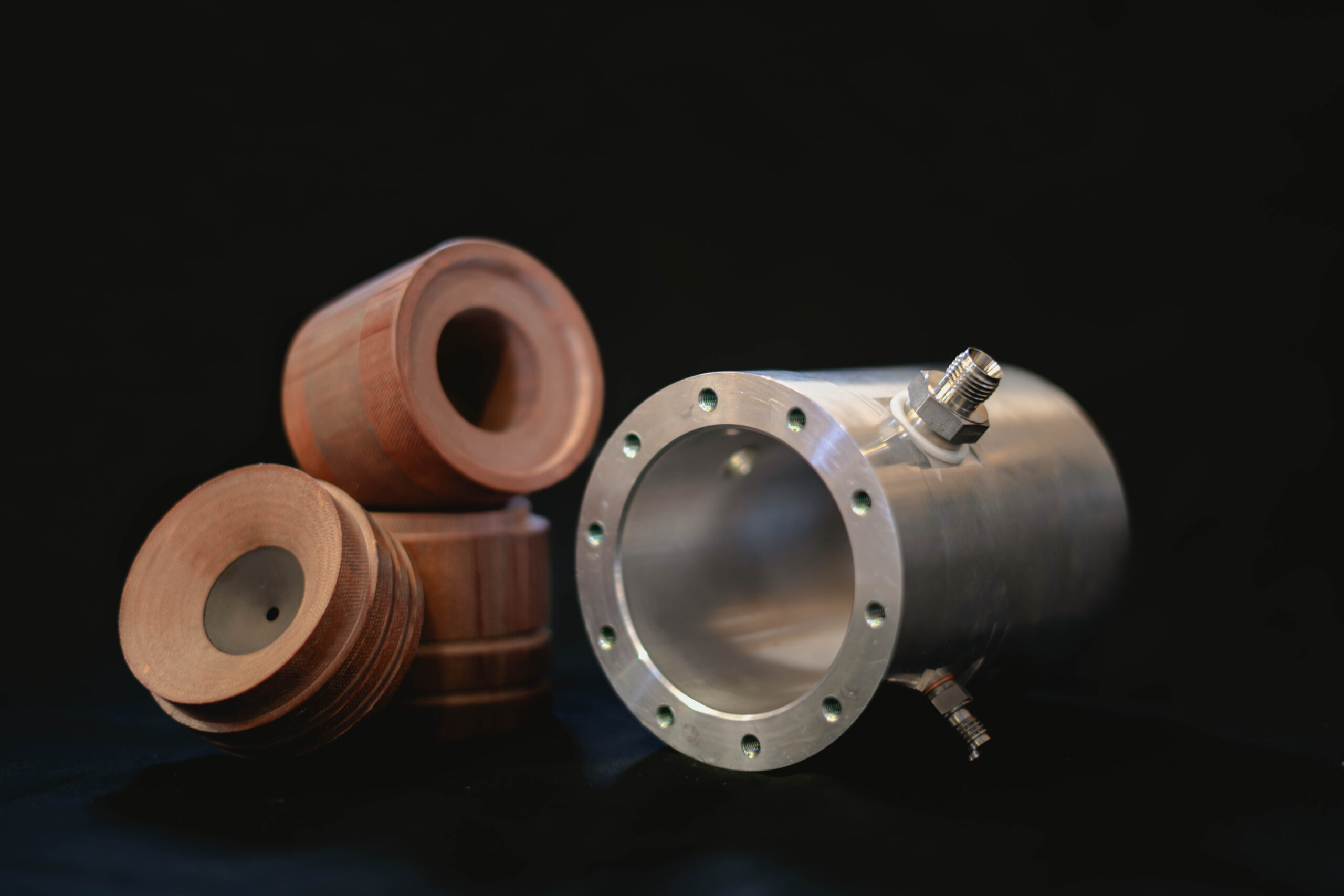

During Project BLAST, the propulsion subsystem will focus on developing the liquid engine „C2H5OH Academic Demonstrator“, or CHAD. Its final version will be named Kilo CHAD, since its thrust will lie within the kilonewton range. The CHAD engines use liquid ethanol as fuel and liquid nitrous oxide as oxidizer. While the first iterations of our liquid rocket engine will be cooled ablatively, additive manufacturing of Kilo Chad will enable us to create the geometry needed for regenerative cooling. TRUMPF has already produced one such engine for us.

In its current form, CHAD has a chamber pressure of 60 bar. This is achieved by pressurizing the propellants with high-pressure helium. We chose this gas as it is light and inert, and thus will not interfere with the combustion process.

In order to develop a viable engine, we first tested several injector types with water, then with the respective propellants. Following this, we conducted hot-fire tests on a sub-scale engine with a thrust of 550 N. The same procedure is being followed for the regeneratively cooled engines.

Our first design of CHAD features a combustion chamber made from phenolic paper and a graphite nozzle, encased in aluminium. The phenolic paper will aid to cool the engine by ablating during the combustion process. During hot-fire tests, we have measured the pressure within the combustion chamber as well as the pressure before the injector. We have also measured the engine’s thrust in order to characterize our liquid rocket motor.

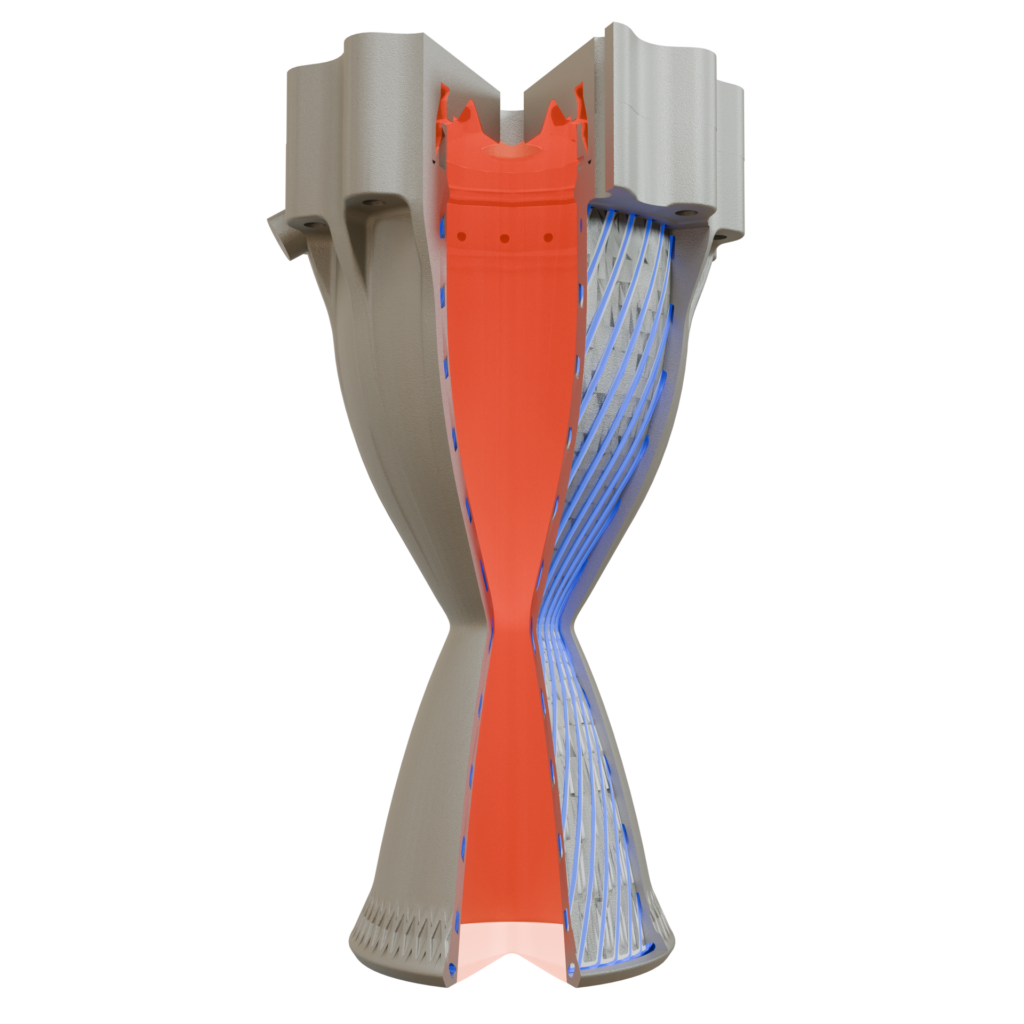

The regenerative cooling capability of the engine will be achieved by having nitrous oxide (blue) circulate through cooling channels within the combustion chamber and nozzle walls of the additively manufactured metal engine. There will be a loss in pressure throughout the cooling channels, which is in part compensated by the warming of the fluid. We will also adjust the pressurization of the propellants in accordance with data gathered during cold flow and hot fire tests.

The aforementioned heating of the fluid changes its density. When nitrous oxide is heated at high pressure, two-phase flow may occur. This refers to a state in which liquid and gaseous flow take place simultaneously. While designing the injectors, we have to take this into account, as well as the varying pressure that may result from the phase changes.

Render of Kilo CHAD with visible cooling channels (blue), with the inside of the combustion chamber represented in red.

Our test bench is located in the Material Testing Institute (MPA) at the University of Stuttgart. The testing setup has been developed in-house by HyEnD members. Its design has evolved with the 10+ hot-fire tests of our 550 N engine we have done over the past months. In you are interested in having a closer look at our testing setup and about how a test day usually looks like, have a look at the YouTube video below!

Ground Support

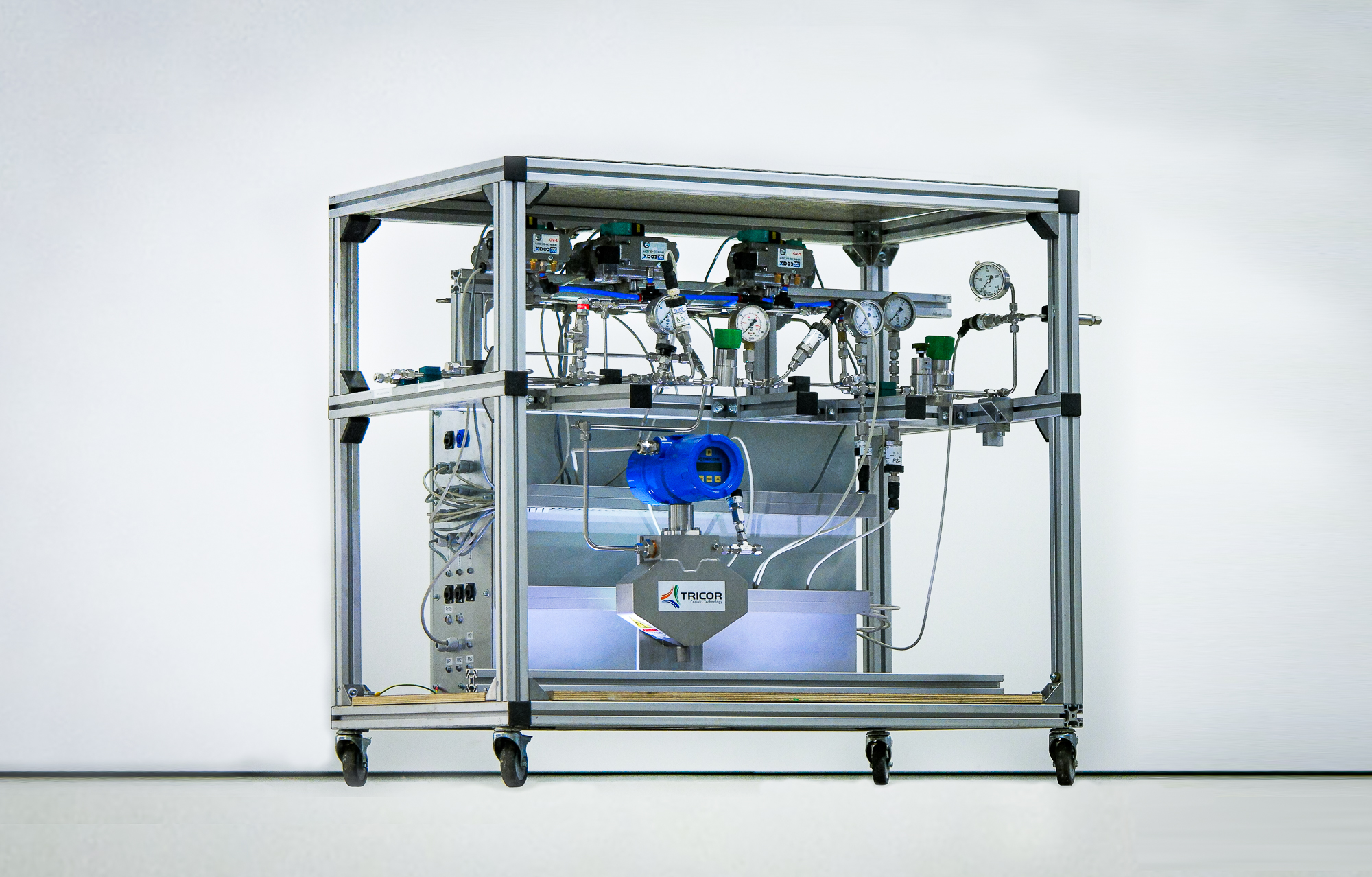

At HyEnD, we are not just building rockets, we are also launching them. This brings up the Ground Support Equipment (GSE) for the upcoming BLAST project. Often the unsung hero, the GSE is critical in ensuring that each rocket launch is executed flawlessly. Without this essential subsystem, our rockets would remain on the ground. It plays an important role in fueling, pressurizing, and guaranteeing the safety of each launch. The GSE is an interdisciplinary subsystem, incorporating thermodynamics, mechanics, electronics, and more.

Our goal for the new GSE is straightforward yet ambitious: we aim for high reliability and adaptability. Building on the success of N2ORTH’s GSE, which operated flawlessly on each launch, we are setting the bar even higher. The GSE is set to tackle all challenges, particularly in managing diverse components such as the propellants nitrous oxide and ethanol, as well as pressurizing gases such as helium and nitrogen.

In order to optimize our measurement, command, and control unit, we are integrating a commercial off-the-shelf data acquisition system. This system promises to enhance our data accuracy and processing capabilities significantly. For BLAST, we are building a new, extended launch rail, made to accommodate our launch parameters. We are also streamlining the fueling processes and hardware, aiming for maximum efficiency and safety. These integrations allow us to be more reliable, flexible, and future-ready.

Are you interested in sponsoring a world-record holding rocketry team? Then take a look at our sponsor presentation!