Project Update

Project Update

We Placed First in the Liquid Category at EuRoC…

From October 9th to October 15th, the HyEnD team participated in the European Rocketry Challenge (EuRoC). We launched our liquid rocket Lumina to about 2.9 km, recovered the rocket in near-perfect condition and won the liquid 3 km flight award! In the overall rankings, we placed second. A great first launch for project BLAST!

Let’s start from the beginning. On October 8th, most of our team arrived in Porto, Portugal, by plane, marking the official start of our on-site campaign. While flying is certainly the fastest way to cross Europe, it quickly leads to an obvious question: how do you transport a rocket on a commercial aircraft?

The answer is simple — you don’t. Instead, two dedicated teams took on the responsibility of driving all the way to Portugal. Their mission was critical: transporting all essential equipment and tools required for the launch campaign. From technical hardware and support equipment to the unmistakably oversized launch rail, their vehicles carried everything that could not be squeezed into standard luggage allowances.

After several long days on the road, countless kilometers, and an impressive level of endurance, both teams arrived safely with all equipment intact. Thanks to their commitment and logistical effort, we were fully prepared to begin setting up operations and focus on what truly mattered: getting our rocket ready for launch.

After all team members and vehicles had arrived at the competition site, setup operations started immediately. The first priority was organizing the paddock area, which served as the team’s central workspace throughout the campaign.

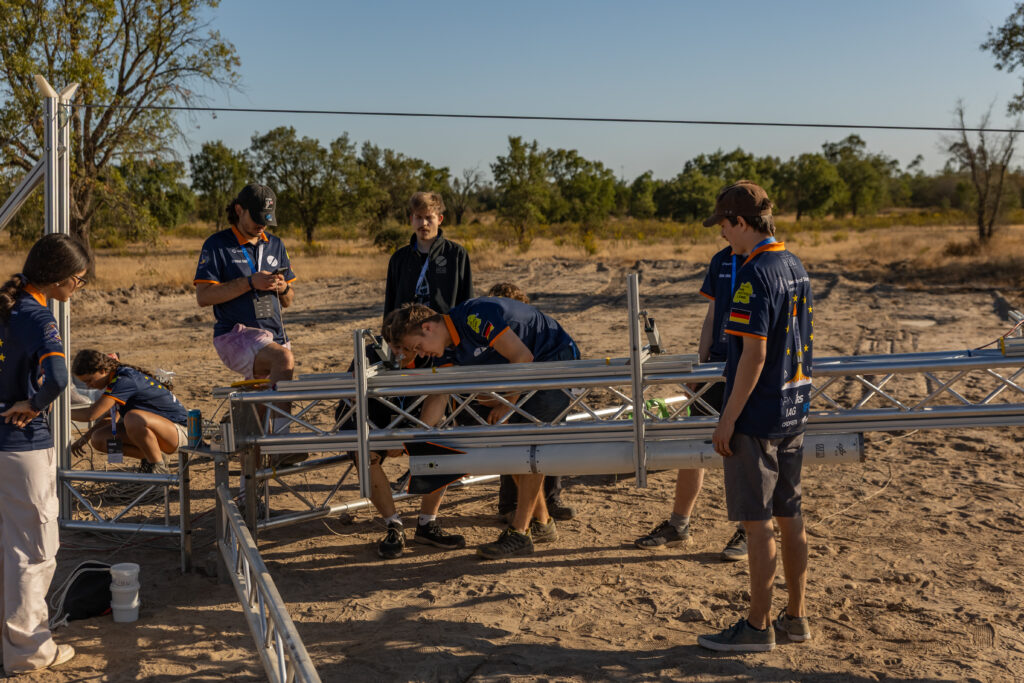

As is often the case with large engineering projects, the final preparations were completed just in time. Even on the last day, small adjustments were still being made to our Lumina rocket. While one part of the team focused on final rocket preparations, other members assembled the launch rail at the launch site and set up the ground support equipment.

In parallel, the ground electronics and fluid systems required for fueling, charging, and launching the rocket were installed and tested to ensure full operational readiness.

The following day, we conducted our Test Readiness Review (TRR). This review is a mandatory step to ensure both launch safety and full compliance with the competition regulations. Although a few compliance issues were identified during the first attempt, the team was able to resolve them quickly. As a result, we successfully passed the review on our second attempt. This marked an important milestone and brought us one step closer to the culmination of a year’s worth of development and preparation.

On the next day, the team arrived at the launch site before 8 a.m. to begin rocket assembly and final launch preparations. Despite having passed the Launch Readiness Review (LRR), unexpected issues occurred during system integration at the pad. As these problems could not be fully resolved within the assigned launch window, the team made the decision to postpone the launch for that day in order to avoid unnecessary risks. However this meant that the next day we had to launch – as this was the last day of the EuRoC 2026.

We tried to launch in the first launch window of the day. The rocket was on the pad and everything was going according to plan. As one of the last steps of the launch preparation we started fueling the rocket.

Since nitrous oxide (N₂O) partially vaporizes at higher temperatures, a controlled venting procedure was required in order to maximize the amount of liquid oxidizer in the tank. However, during the first venting operation, an unexpected event occurred: the parachute system was triggered and the drogue chute deployed. This in return meant that we missed the first launch window

Subsequent analysis indicated that vented nitrous oxide entered the rocket structure, causing a pressure increase inside the avionics bay. Because the flight computer determines apogee using barometric pressure measurements, this sudden pressure variation was interpreted as a rapid altitude decrease, which unintentionally triggered the deployment logic.

Since it was the last launch day, time was running low. After making sure all gases would vent to the outside of the rocket and re-packaging the parachute, we were back on the launch pad during the last launch window.

Once again, the fueling procedure for the rocket was initiated. However, not everything went according to plan. During venting, not only the pressure but also the temperature decreased, causing the vent valve to freeze in the open position. Fortunately, ambient temperatures in Portugal in mid-October were high enough for the valve to thaw after a short time, allowing the fueling process to continue. By shortening the venting intervals, the cooling effect was reduced and the rocket could be successfully pressurized to its nominal operating pressure.

Now it was time for launch. The next few seconds would show if every system works as expected. lthough every subsystem had been tested multiple times, a degree of uncertainty always remains in the moments leading up to liftoff.

The countdown began at 15 seconds. Everybody was focused on the launch rail in the distance to not miss anything, while closely monitoring the official communication channels.

Then liftoff!

The rocket left the launch rail at a velocity of 30.5 m/s and reached an apogee of 2.9 km, achieving a maximum speed of Mach 0.74. However, reaching altitude is only one part of a successful mission. The second half depends on the seamless interaction of the avionics, recovery, and structural subsystems throughout the rocket’s design and operation.

Would the flight computer trigger parachute deployment at the correct moment? Would the recovery bay open reliably to allow chute extraction? And ultimately – would the parachutes deploy as intended?

Everybody is searching the sky trying to find the rocket and hopefully see a successfully deployed drogue chute. The launch itself was already a success, however if the chute does not open the rocket will follow a ballistic trajectory and will most probably destroyed on impact. In that case most of our recorded flight data would be lost permanently.

But not this time. Both drogue and main chute deployed at the correct altitude. The rocket descended slowly, drifting downrange.

After the launch window closes, it’s time to recover Lumina. After a nominal touchdown at 7 m/s, the rocket is in one piece and still pretty as ever, albeit with a few scratches. Great work, recovery team!

The next day, we get the reward for all our worries and effort: a trophy for the best liquid 3 km flight and second place in the overall ranking!

Want to watch the launch? For now, you can only rewatch the EuRoC stream. But our EuRoC 2025 aftermovie is comming soon.