Project Update

Project Update

N₂ORTH Integration and Alignment Process

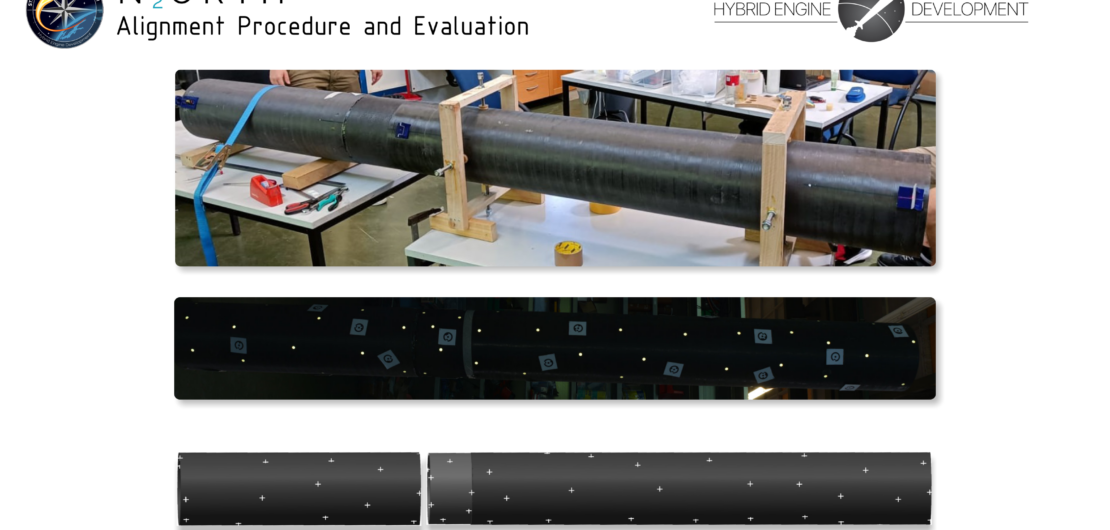

HyEnD has started the integration process of its N2ORTH rocket for the launch in Esrange later this year. One of the most crucial aspects of the rocket assembly is to ensure precise alignment of the components. Every slight deviation can have an influence on the flight trajectory and has to be considered in the mission analysis.

We achieve alignment by using a laser beam and photogrammetric measurements: First, the laser beam is aimed over a notch in order to align it with the tank axis, which was determined in a previous process. For the next step, the tube connector is inserted partially into a segment of rocket structure. Two targets are placed onto the structure segment aligned with its axis. The targets consist of grids perpendicular to said axis. After that, the structure segment can be aligned to the tank axis. Alignment is achieved when the laser beam intersects the two grids at the same point. Next, the tube connector is connected to the tank with a small amount of epoxy.

In order to evaluate the alignment, photogrammetry is used. This method generates point clouds to which cylinders can be fitted using CAD software. The offset and angle between the different parts then can be analyzed. Different plausibility checks are performed in order to ensure that the obtained measurements are viable.