Project Update

Project Update

Successful Validation of Thermal Protection System

In order to complete final research concerning thermal loads, HyEnD conducted thermal tests on December 20th, 2022. The thermal tests were a crucial milestone and provided us with valuable insights into the expected in-flight behavior of N2ORTH.

During a test campaign, we tested the nose cone, fins, and 3-ring system of the parachute. The tests were conducted under realistic conditions corresponding to a speed of Mach 2.5, equivalent to the predicted max Q conditions. Thus, with this test, the maximum aerothermal load that we expect during our flight could be tested.

First the fins were tested. Due to the surface standing perpendicular to the flow direction, high heat loads are expected here. During the test, the leading edge of the fins was able to withstand the thermal load expected at max Q for over a minute. This is significantly longer than expected in flight, so we are confident in our design.

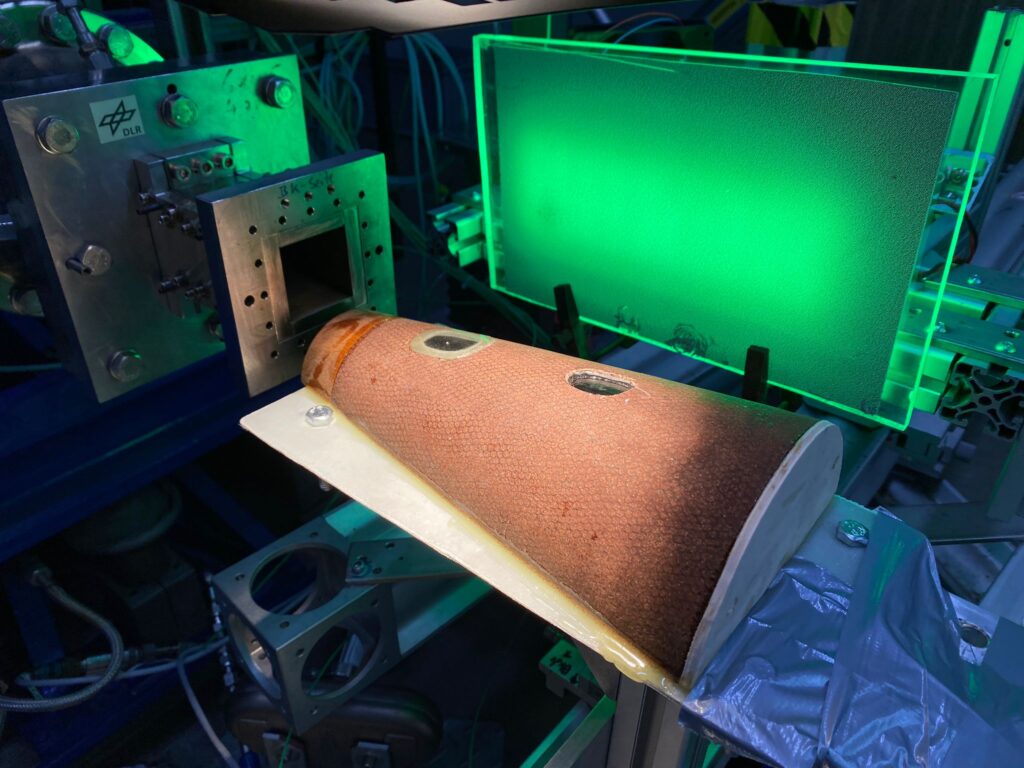

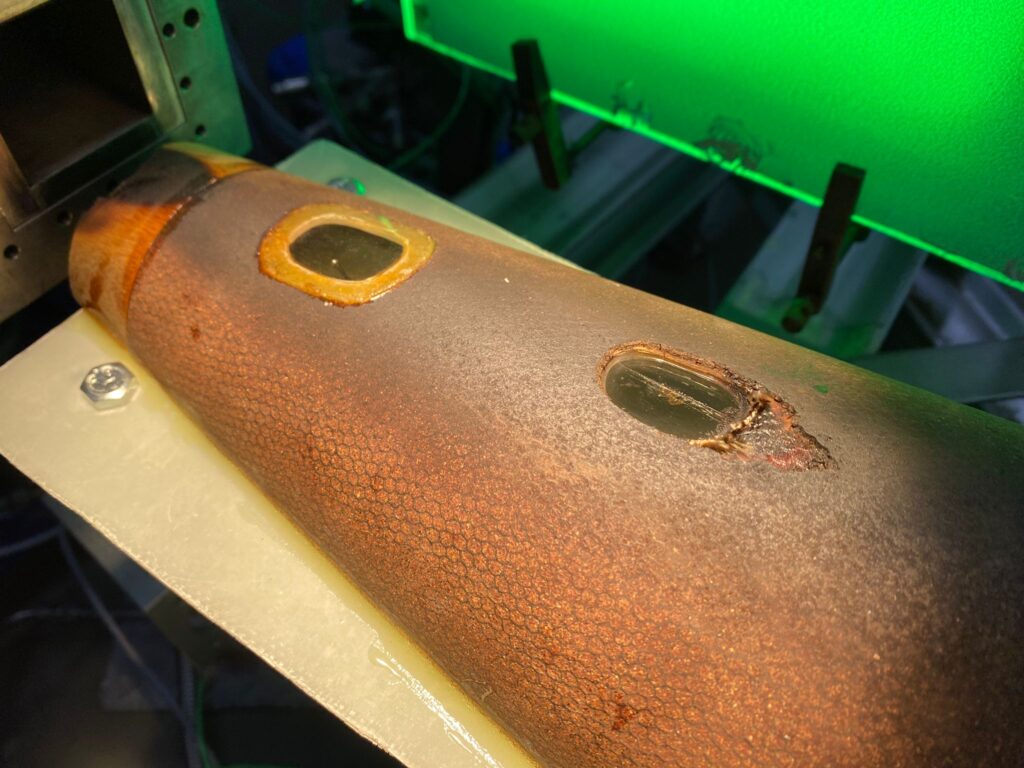

Subsequently, the nose cone was tested. We tested not only the structure of the nose cone, but also potential camera recesses. We confirmed that the thermal loads can be safely withstand even at the location of a recess. With this test, we validated for a second time that our thermal protection at the nose cone can withstand the loads with a high degree of reliability.

By testing the 3-ring-system of the recovery, it should be verified whether a premature triggering of the pyro-cutters can occur due to the heat load. It should be mentioned that our recovery system will never be exposed to such thermal stresses during our flight compared to max Q. In order to perform a maximum estimation here as well, the system was also tested at max Q conditions. The thermal tests showed that the cutters are not triggered prematurely by thermal stresses. In a subsequent test in which the cutters were intentionally triggered, it was demonstrated once again that the 3-ring system reliably releases the connection when the cutters are ignited.

Many thanks to the DLR Institute of Space Propulsion in Lampoldshausen. Due to their support at the M11 test bench and access to the air heater for supersonic tests, we were able to successfully carry out our tests.