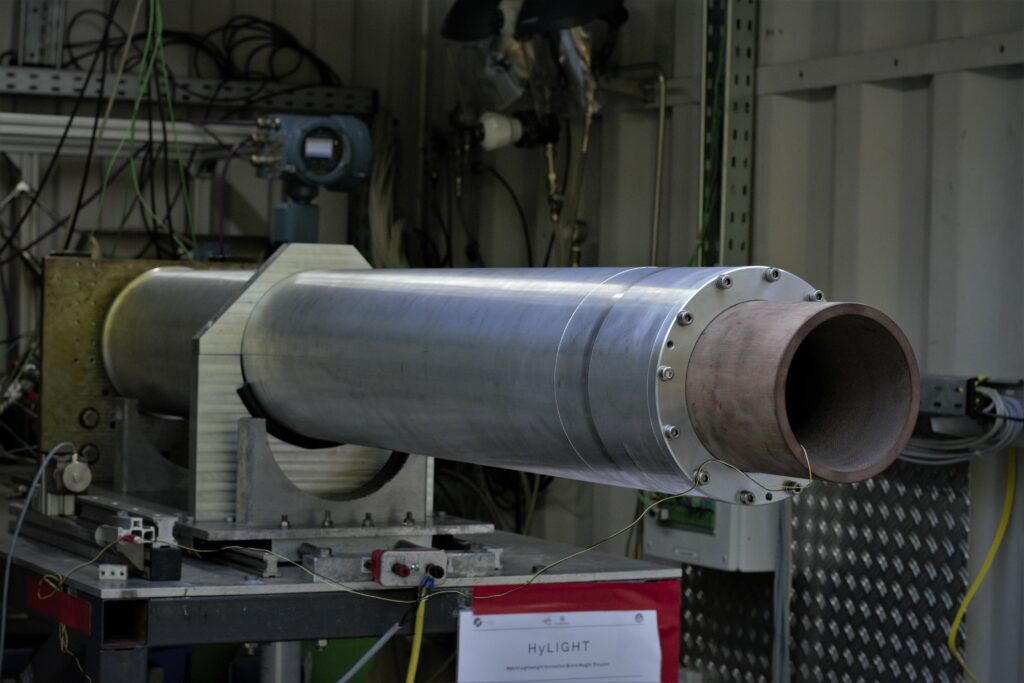

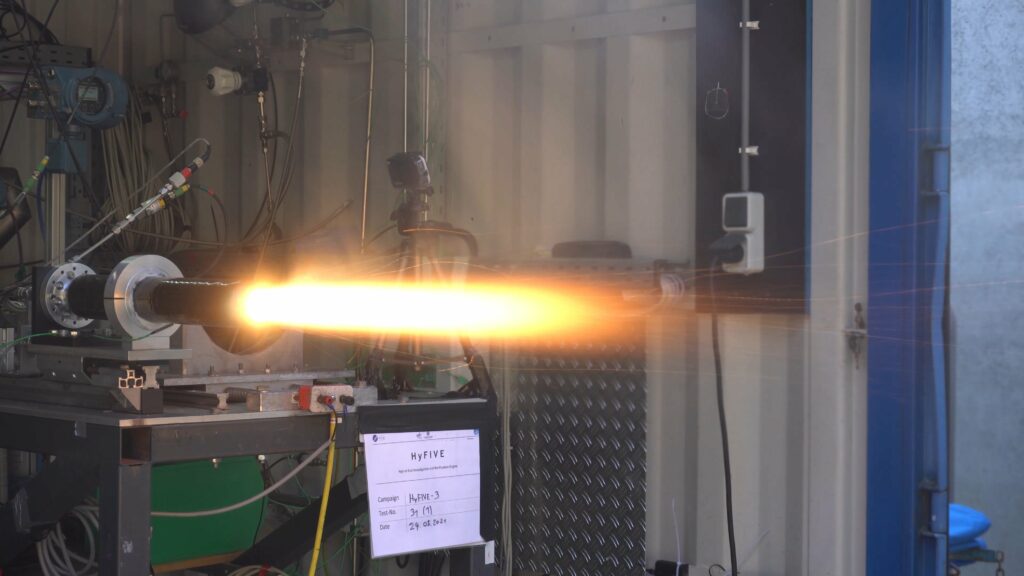

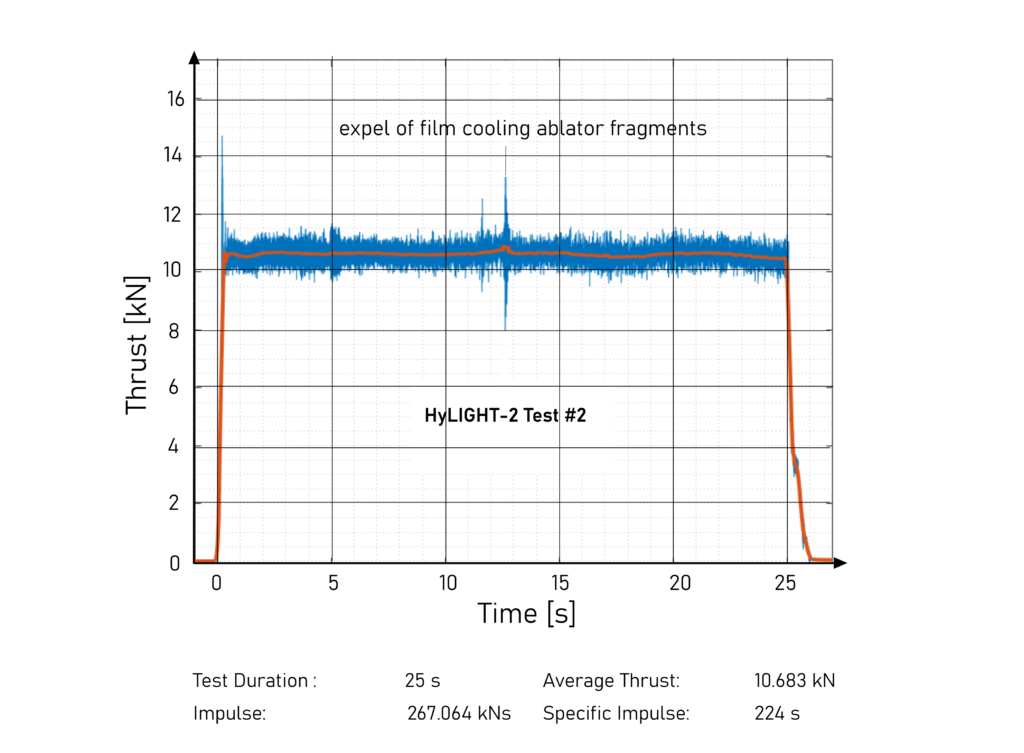

HyLIGHT-2 Engine Tested for 25s

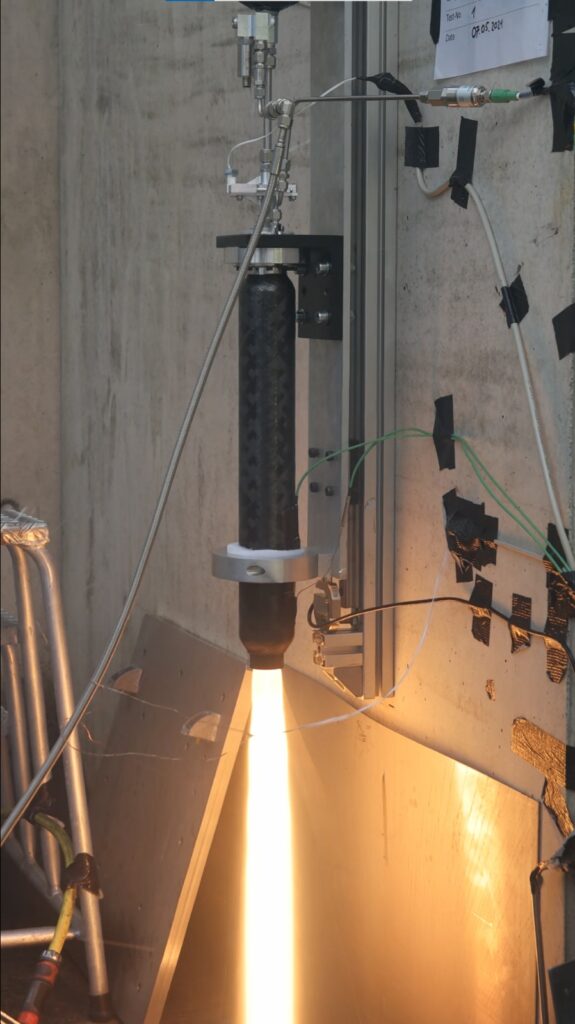

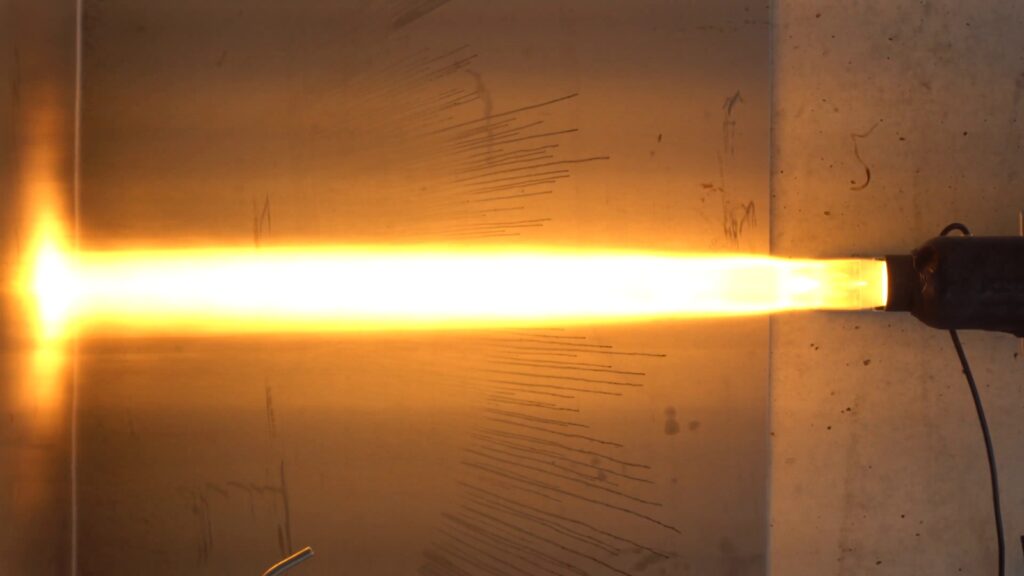

HyEnD is proud to announce that it has tested its HyLIGHT-2 Engine in near-flight configuration for its full intended operation time of 25 seconds. The test was conducted at the test bench M11 of the German Aerospace Center in Lampoldshausen and marks a big milestone for the development of the N2ORTH rocket.

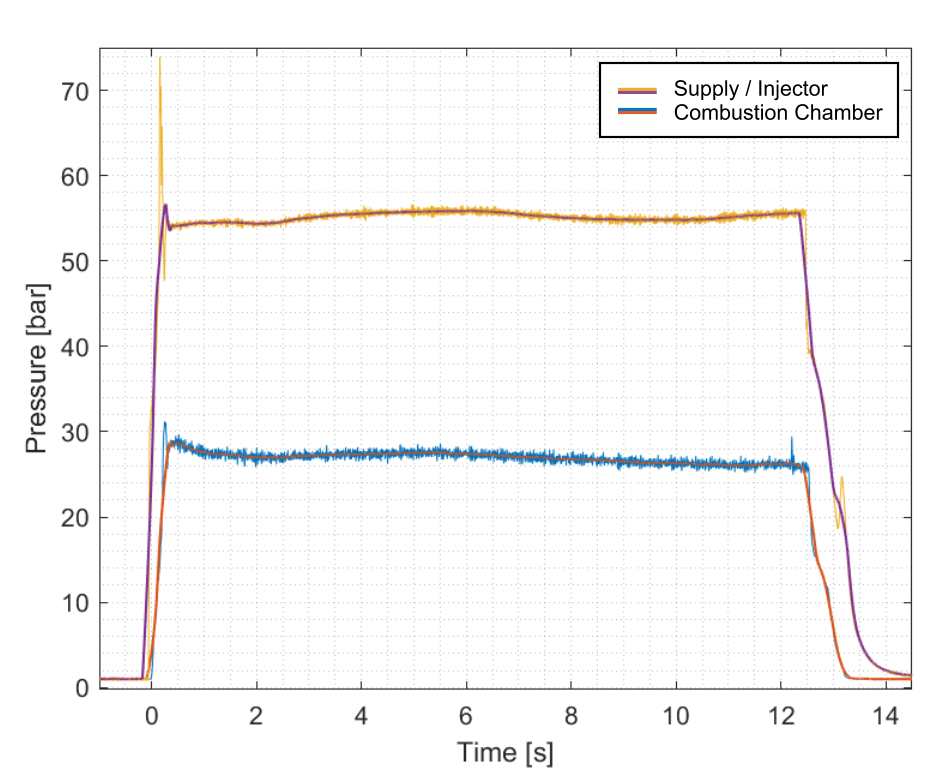

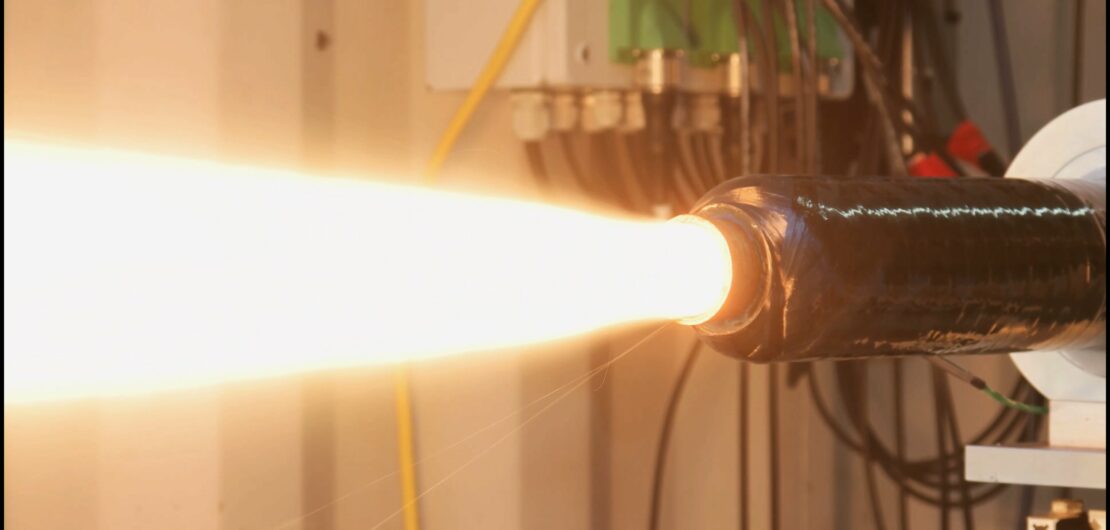

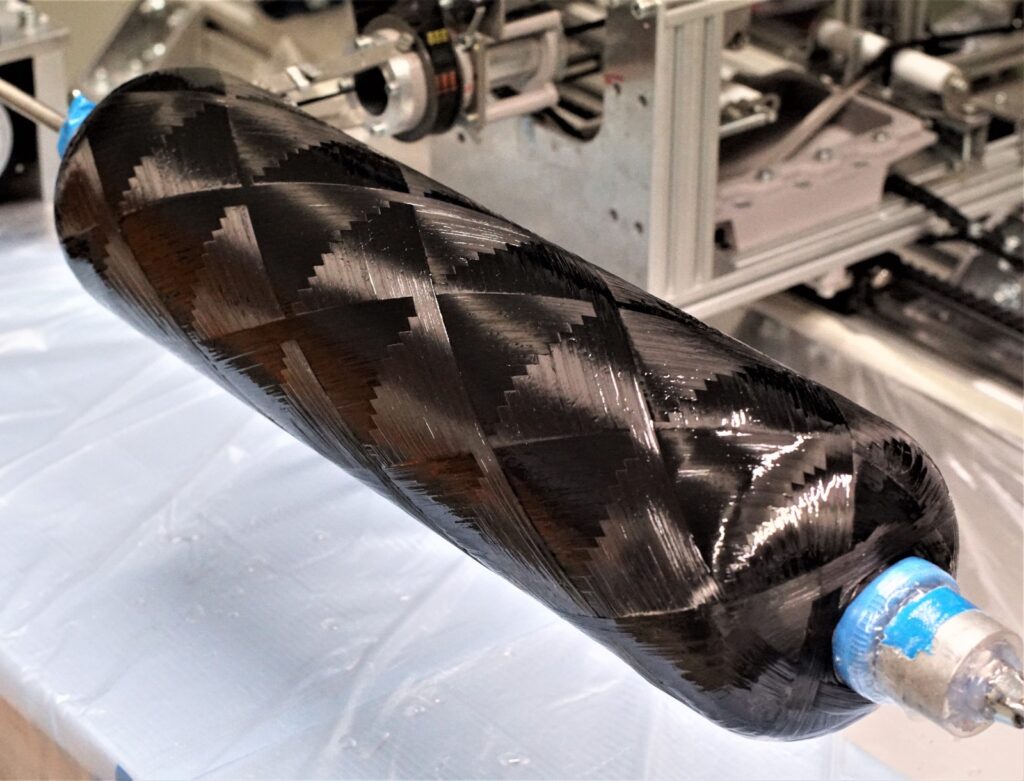

The tested configuration has a dry mass of 13.5 kg and was loaded with 20 kg HTPB-based fuel. In addition, 2 kg of HDPE are located in the post combustion chamber in order to function as a film cooling ablator for the nozzle section. The multi-element swirl injector and graphite mixer in the post combustion chamber ensured a high reaction and overall engine efficiency, resulting in a specific impulse at sea level of 224 seconds. Operating at 30 bar chamber pressure and an oxidizer to fuel ratio of 6.07, an overall impulse of 267064 Ns was achieved.

The next test with minor optimizations of the design is scheduled for end of March. This test will be the final static test and will qualify the engine design. For April and May, integrated tests in blow-down configuration together with the rockets oxidizer tank, fluid system and ground support equipment are planned.

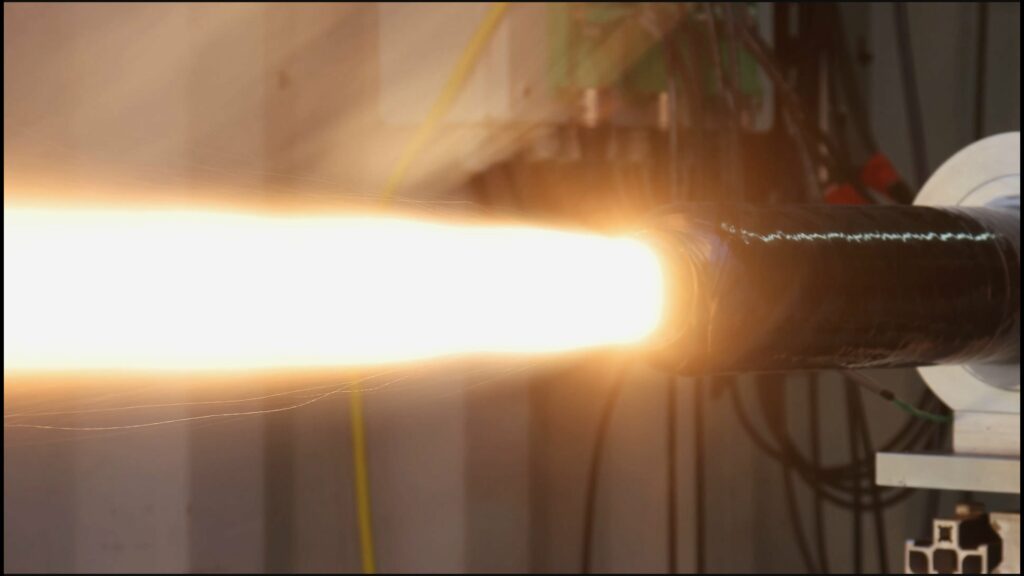

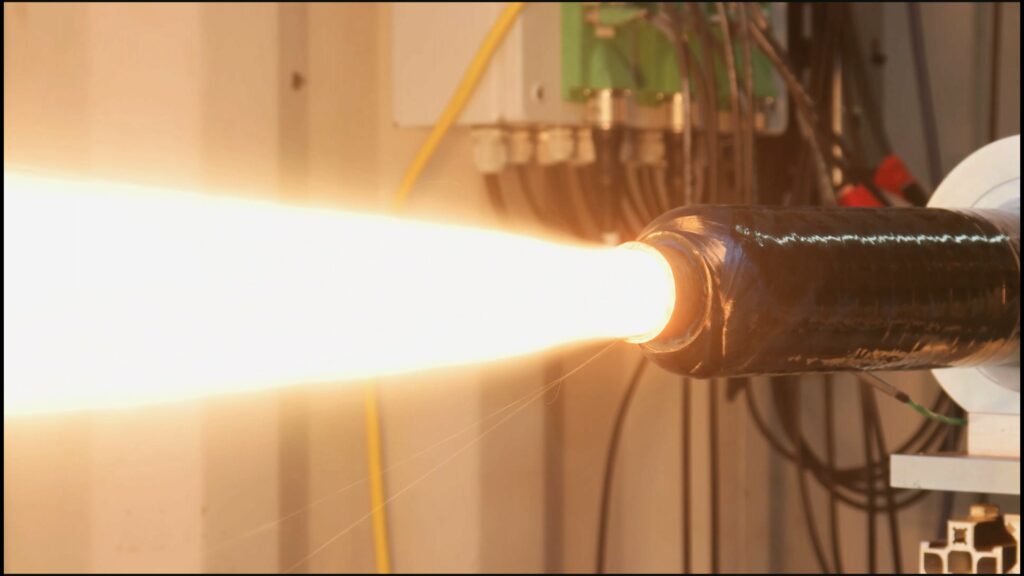

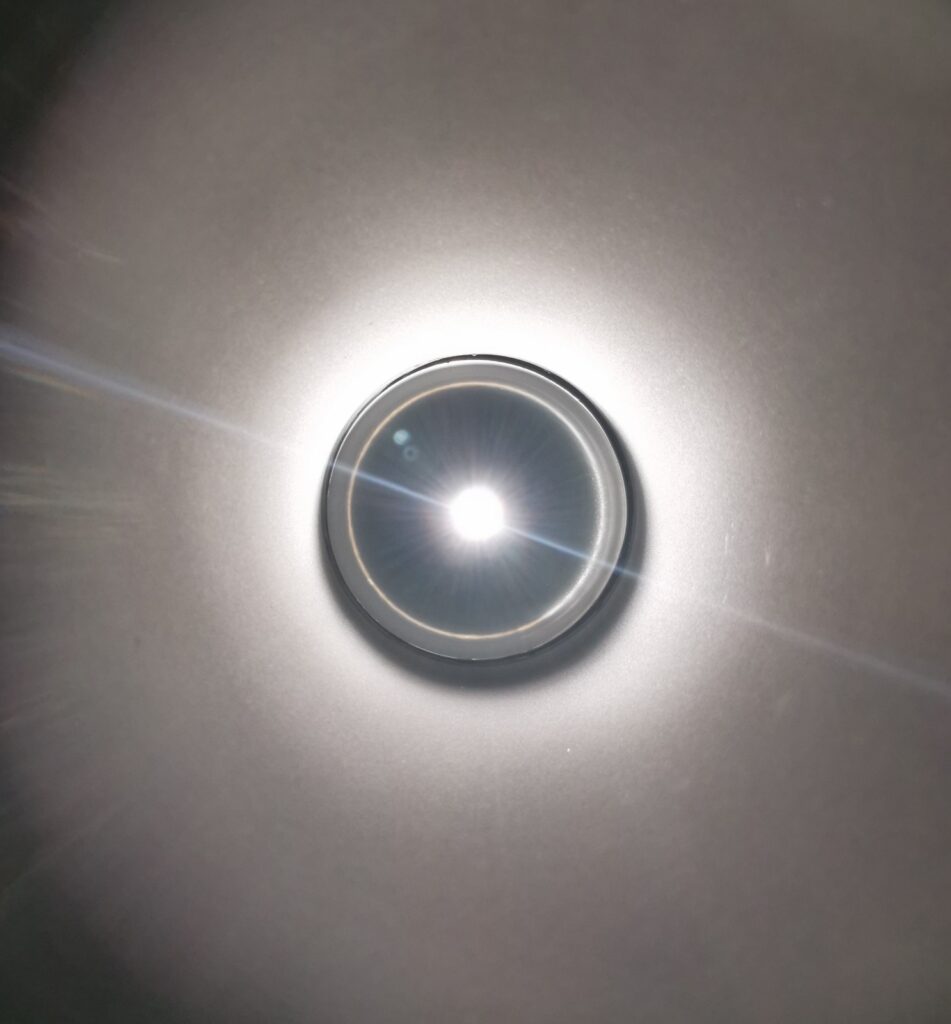

Take a look at the video of the test: