Announcing: N2ORTH-3

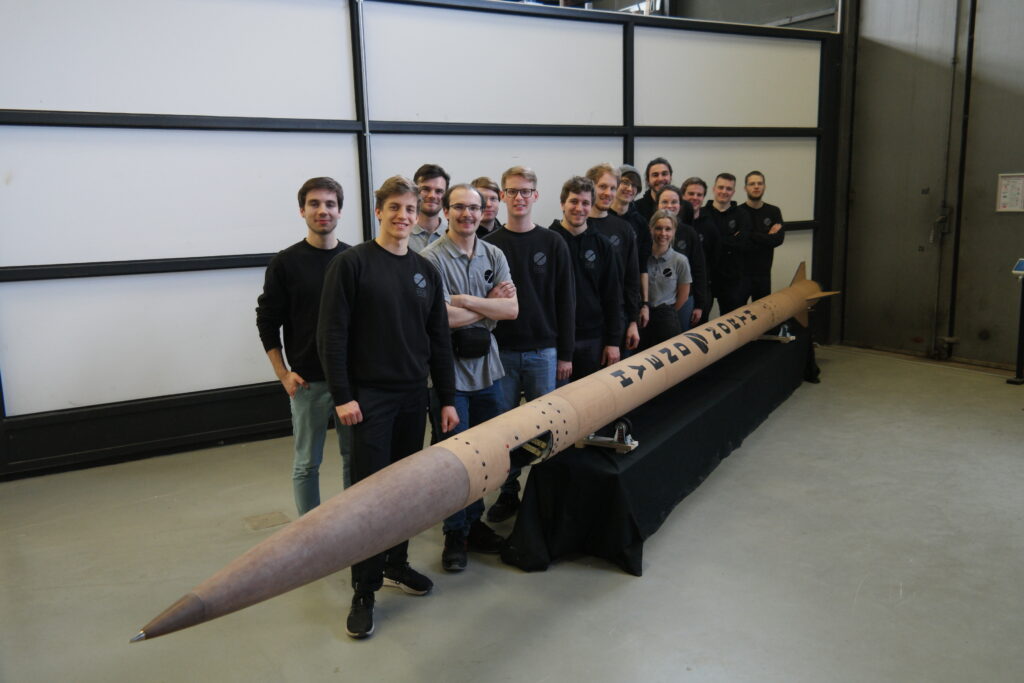

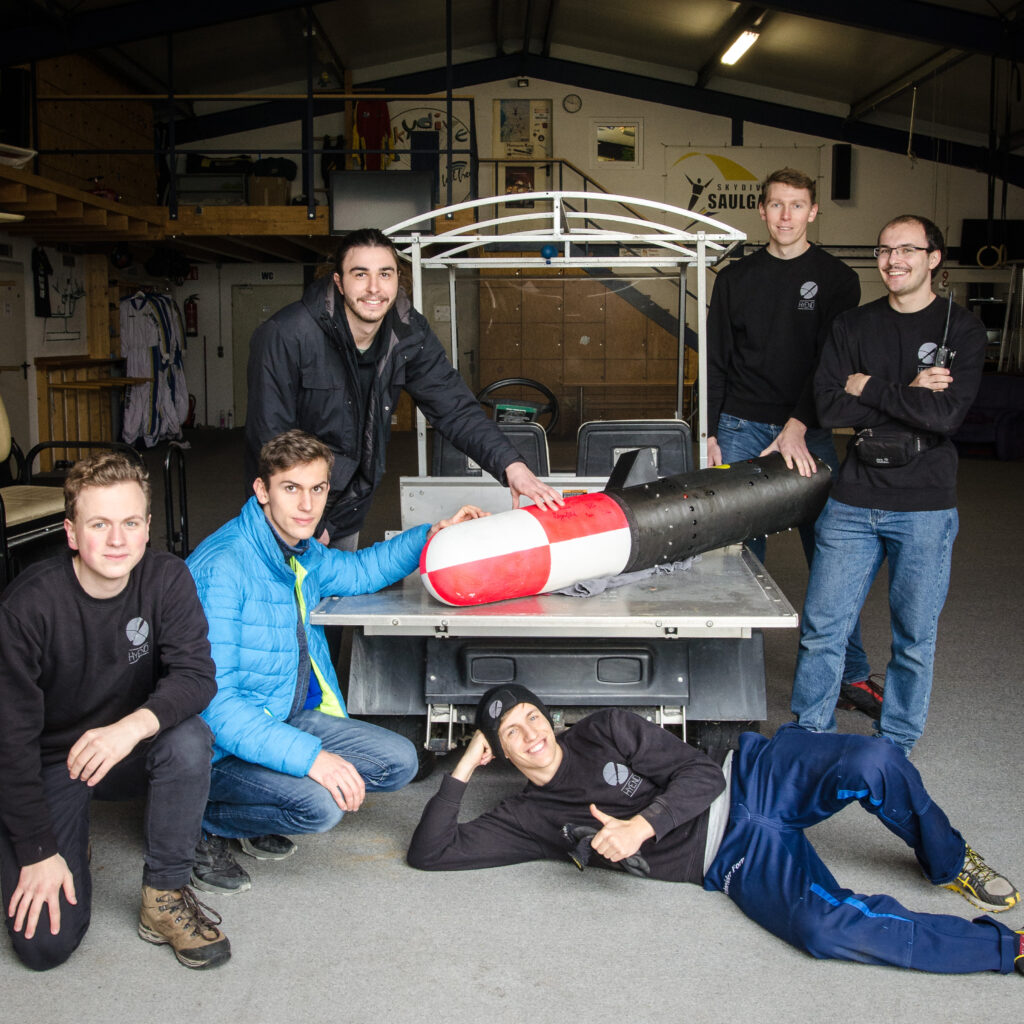

We’re launching another N2ORTH rocket: N2ORTH-3!

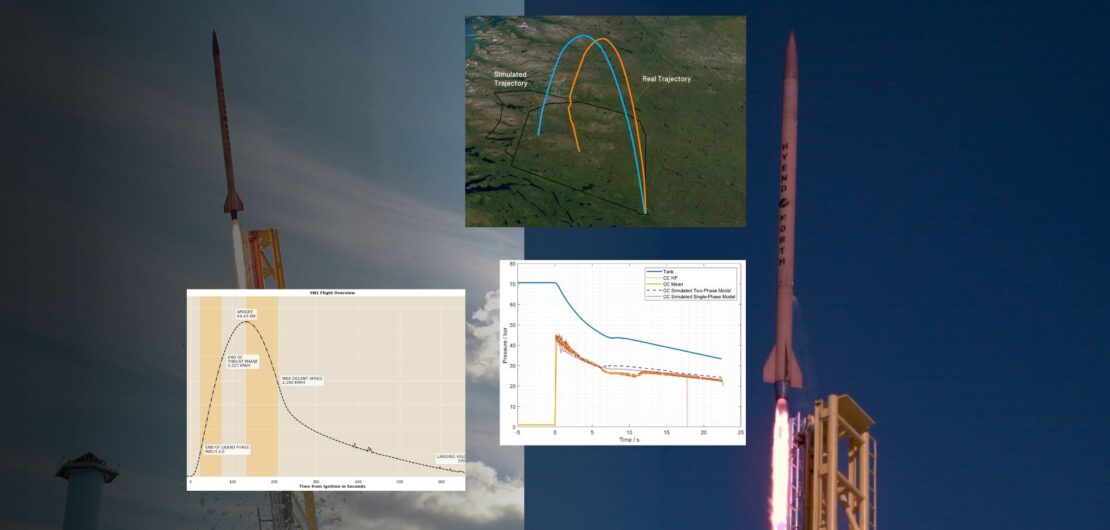

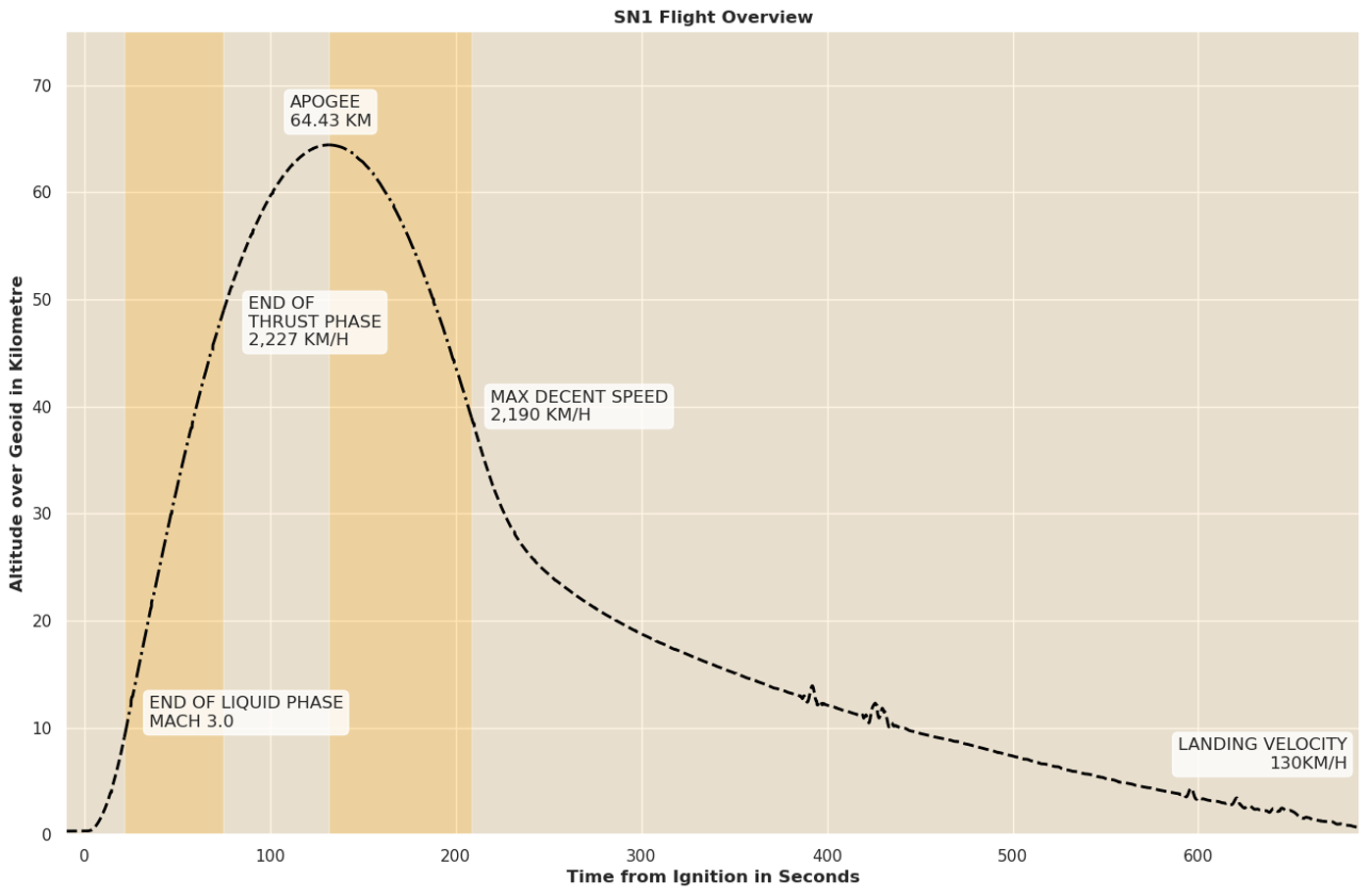

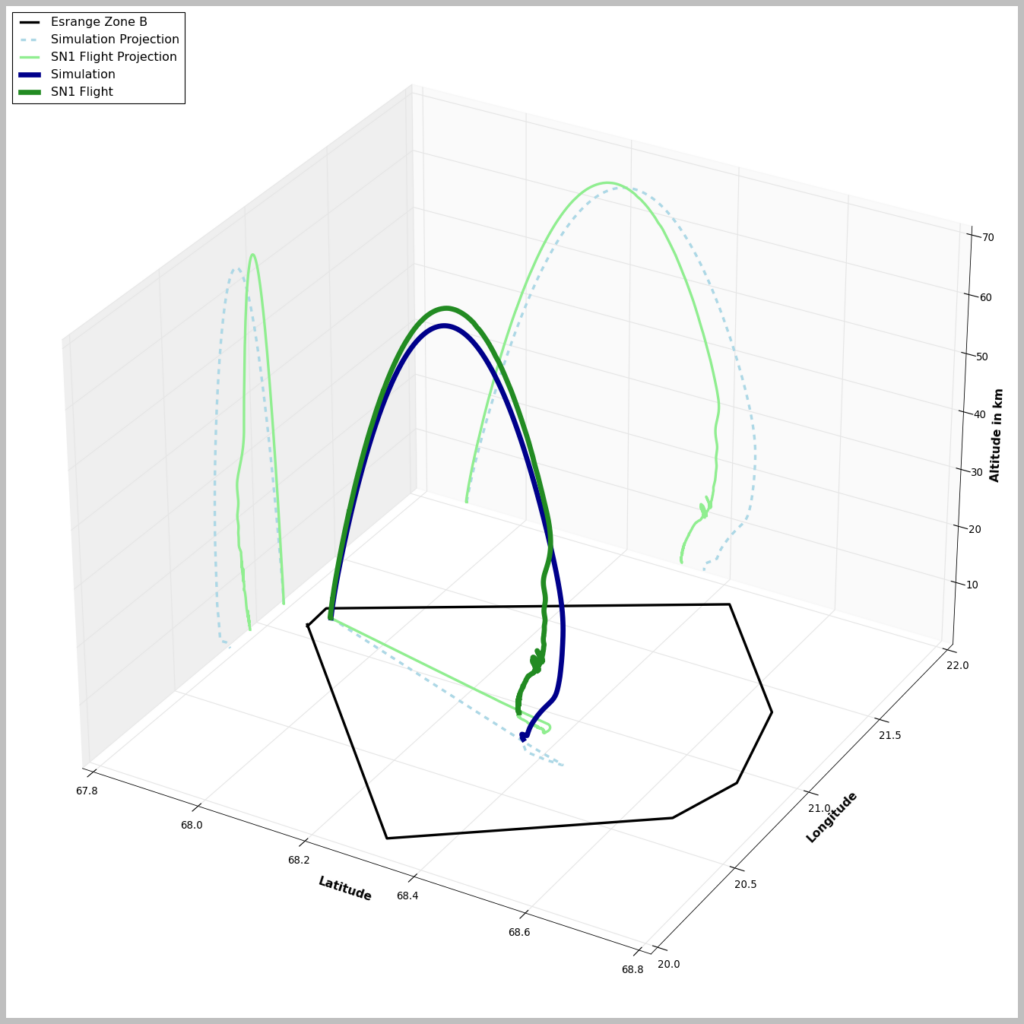

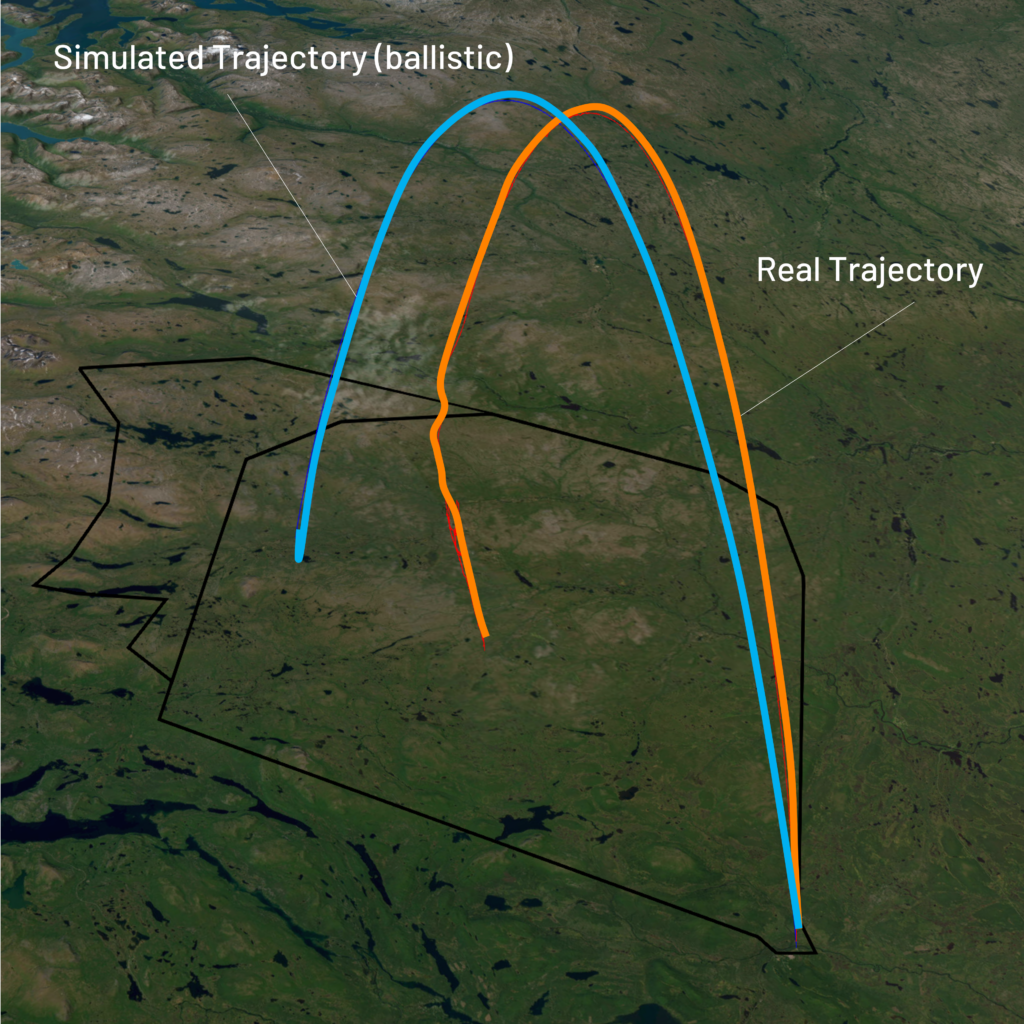

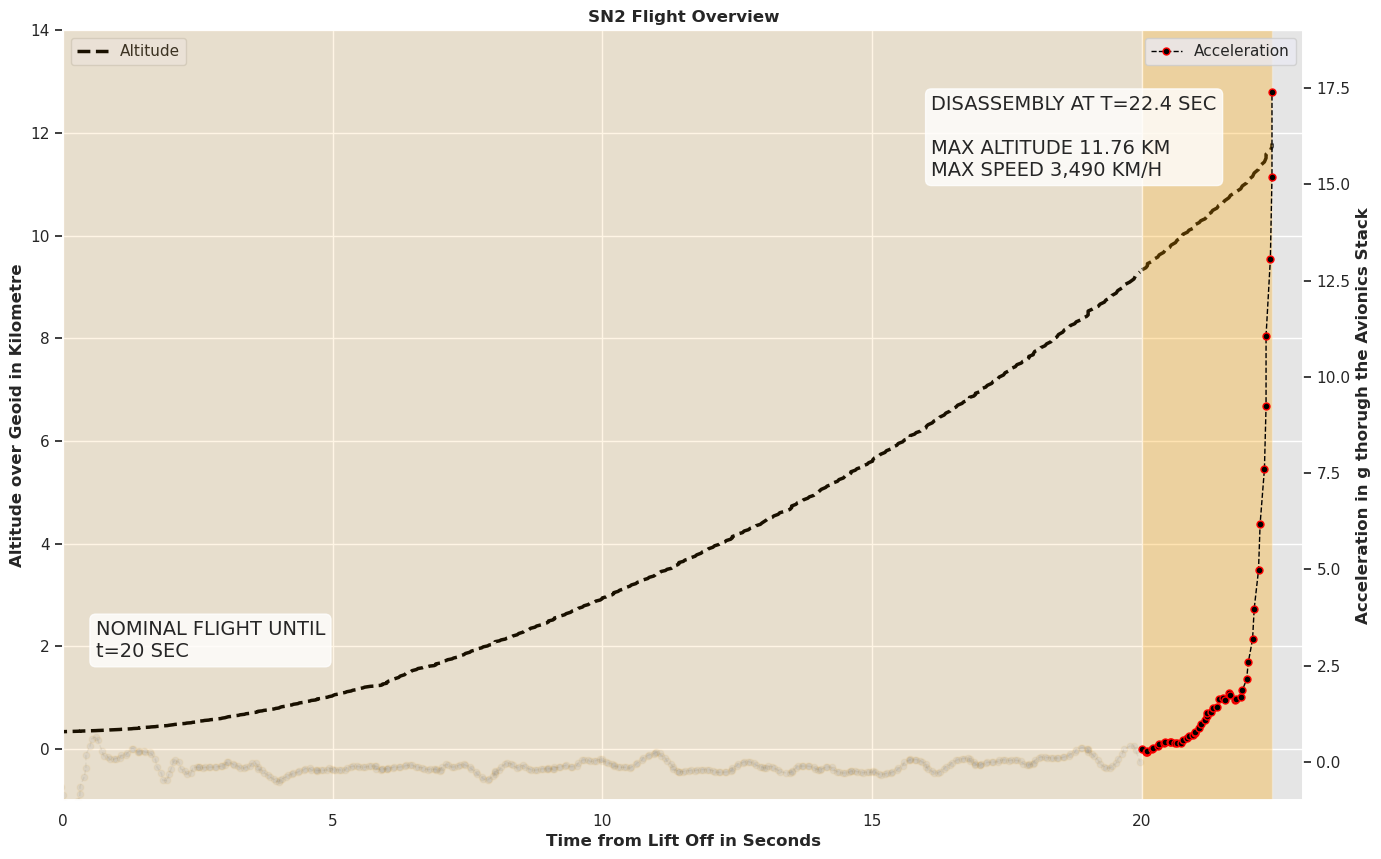

For the first N2ORTH launch campaign, HyEnD has built two complete rockets, one of which set the new student built hybrid-rocket altitude record, reaching an apogee of 64.4 km. However, the team also manufactured spare components of key elements like the oxidizer tank, a spare engine and several valves. With these components in store, the idea emerged to build a third rocket and attempt again what the second rocket was set out to achieve: becoming the first European student team to reach space and the first worldwide to do so with a hybrid rocket.

Thus, the N2ORTH-3 project came to life, running in parallel to HyEnD’s main project, BLAST.

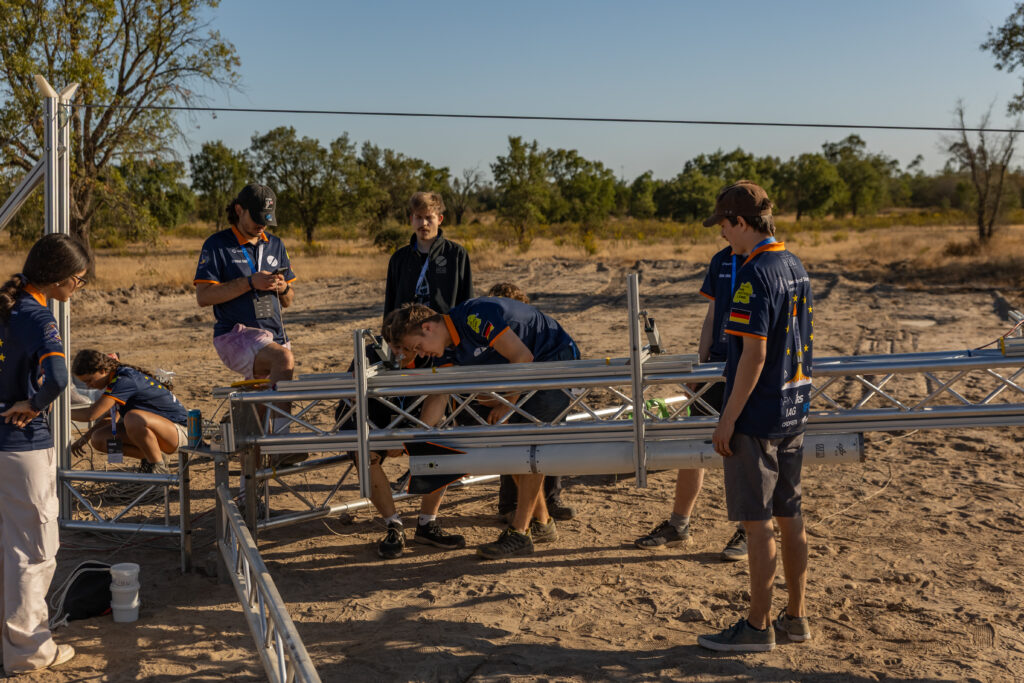

Over the past two years, post-flight analysis of the two flights was conducted, new structural components were manufactured, old parts reinforced. Recovery hardware was redesigned, manufactured and tested, a new flight computer designed and the GSE reworked.

Now, in November 2025, the rocket is nearing completion and has already passed several test integrations. We are getting ready for our next big launch and a new attempt to write history.

Here are the changes to the N2ORTH rocket’s original design:

Recovery

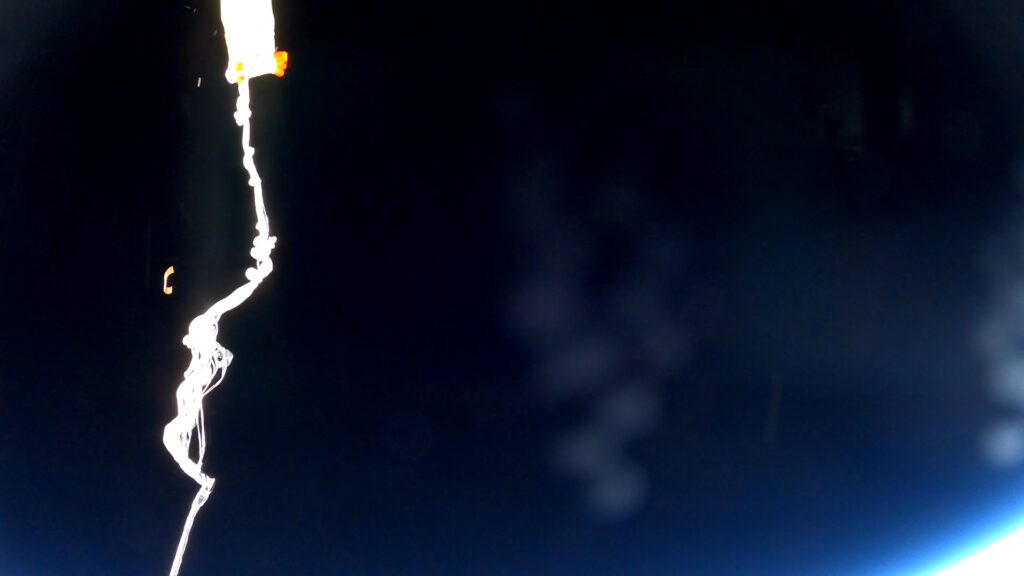

The first N2ORTH rocket demonstrated that even with a non-nominal recovery sequence, the airframe and onboard data was able to survive a tumbling fall from 36 km. For N2ORTH-3, the goal is to replicate this descent mode.

The two-stage recovery system was replaced by a single-stage supersonic drogue chute which was fully designed and manufactured in-house.

The chute is designed to match the drag of the fins to bring the rocket down in a horizontal orientation, reducing impact loads and enabling recovery. Due to the lighter and more compact design, the chute ejection was changed to a top-mounted mortar design.

Overall the changes to the recovery system greatly reduce complexity, reduce the rockets length by 0.8 m and the dry mass by 8 kg. Removing the sideways recovery bay also eliminates one of the main structural weaknesses.

Structures

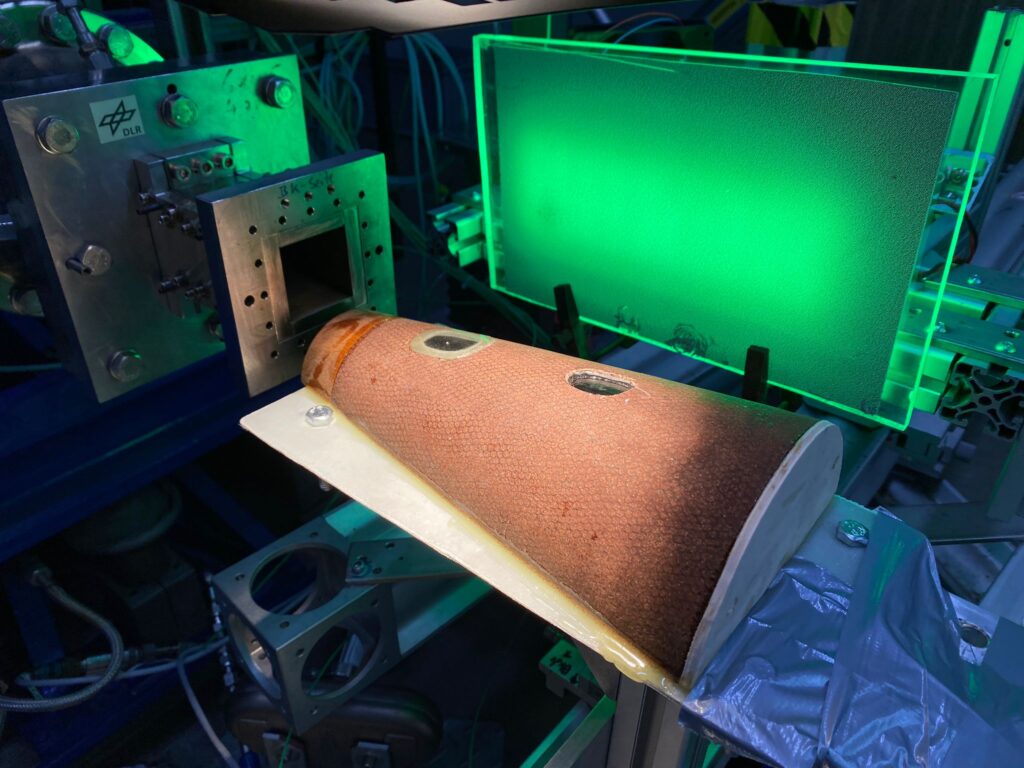

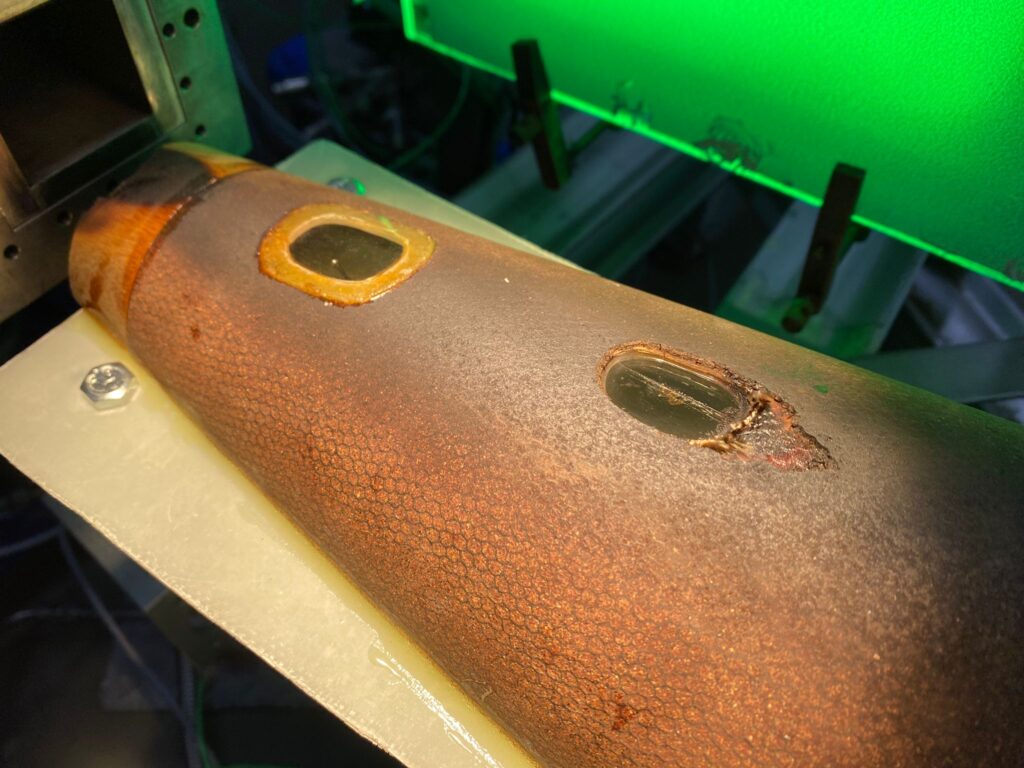

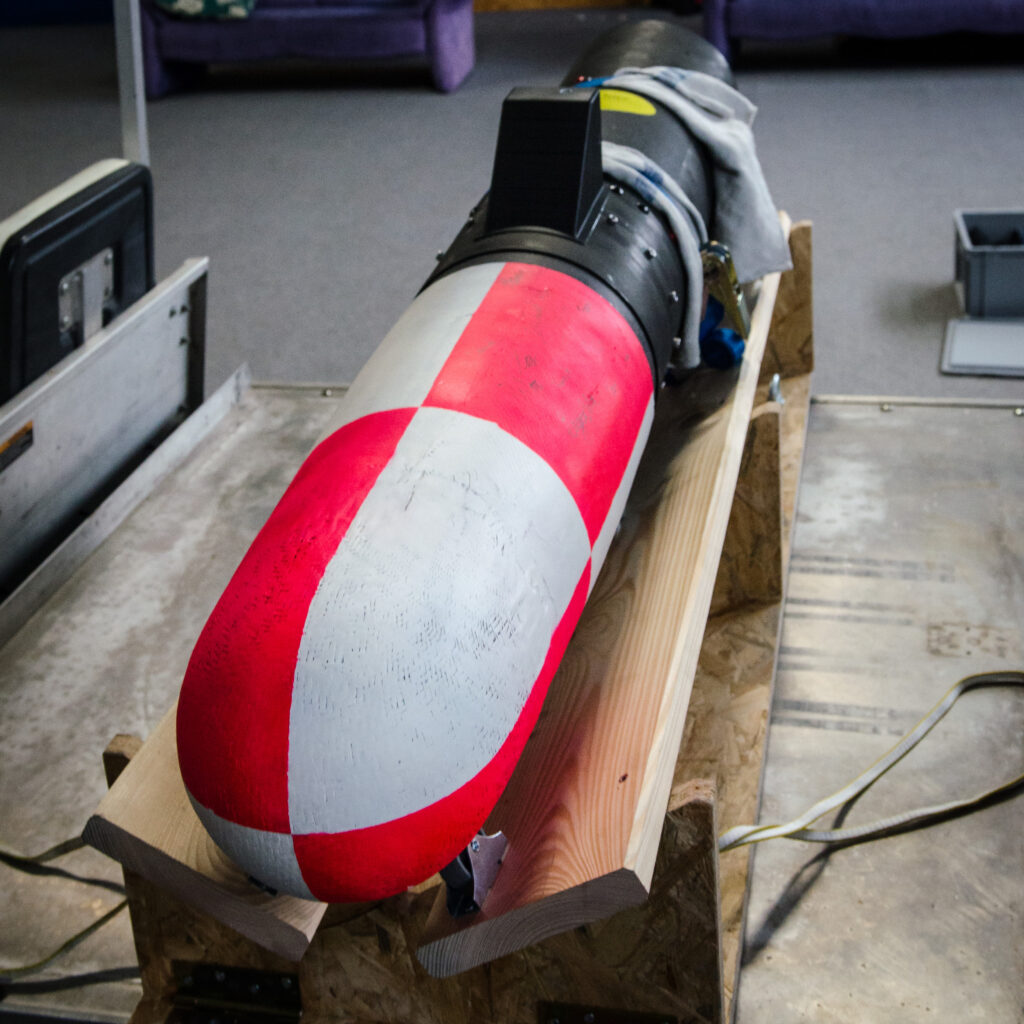

Like on the first rockets, the central structural component is the oxidizer tank. N2ORTH-3 uses a spare Type-III COPV from the first N2ORTH campaign. It is an integral structural tank, including structural connectors for the fin can and nosecone sections, a cable raceway for electronic communications, and thermal protection.

One of the main improvements of the structural integrity of N2ORTH-3 in comparison to its predecessors, is the increased wall thickness of the structural connectors. Using an additional reinforcement tube and additional carbon fiber laminate, the reserve factor against expected aerodynamic flight loads is doubled in comparison to N2ORTH-1 and N2ORTH-2.

Through redesigns and improvements of our winding machine and winding software TANIQWind Pro, we were able to produce a fin can section for N2ORTH-3 with only 20% higher structural mass and similarly double reserve factor against aerodynamic loads in comparison to N2ORTH-1 and N2ORTH-2. This was achieved through shallower winding angles enabled through new fiber tensioning mechanisms and adapted layer buildup.

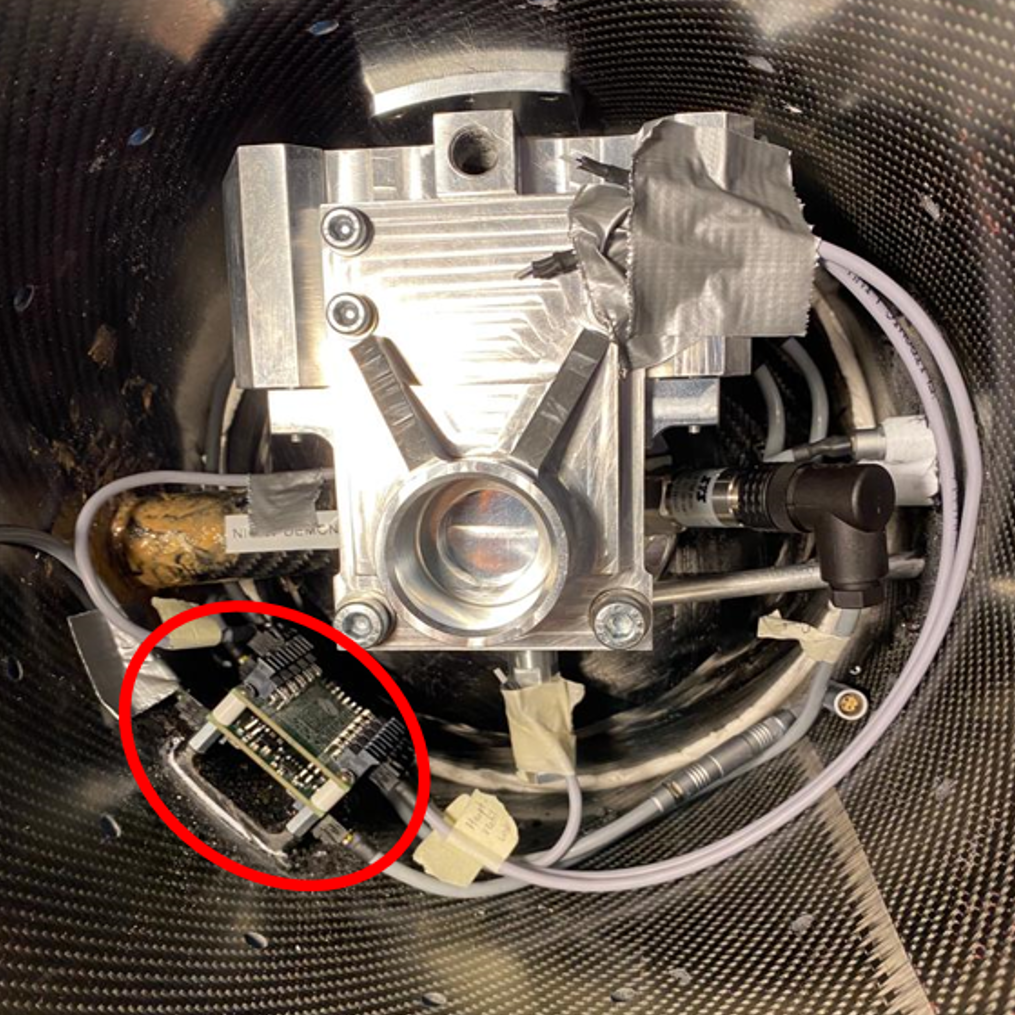

Avionics

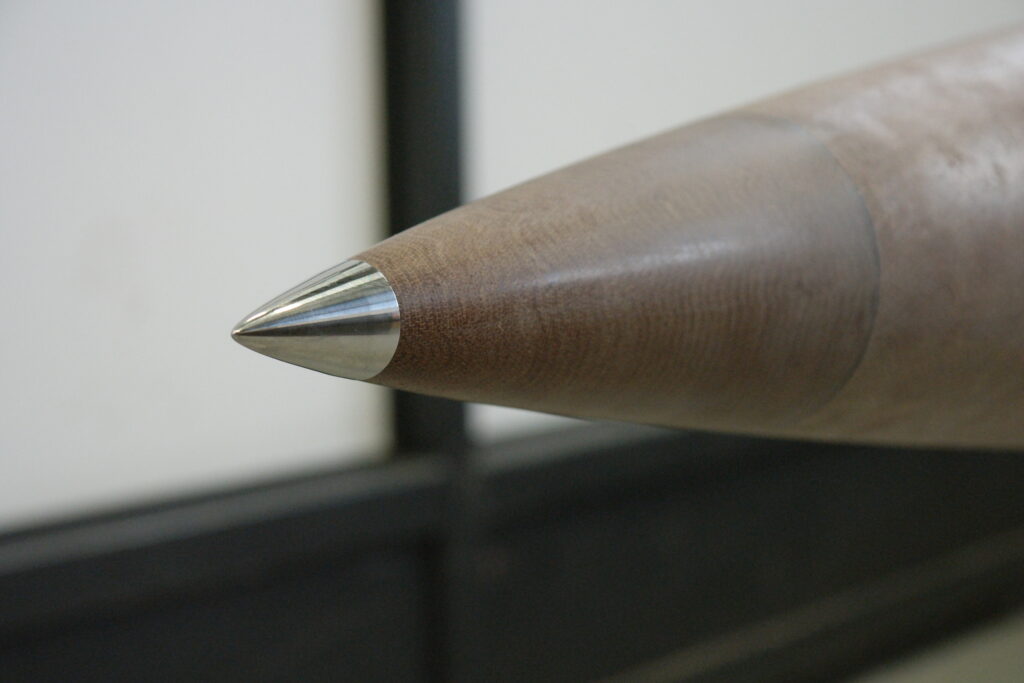

A new nosecone accommodates the updated avionics and the revised top-mounted recovery system.

A new flight computer S2OUTH developed by WüSpace provides telemetry, video transmission, and an upgraded blackbox designed to preserve data even after hard landings.

Propulsion

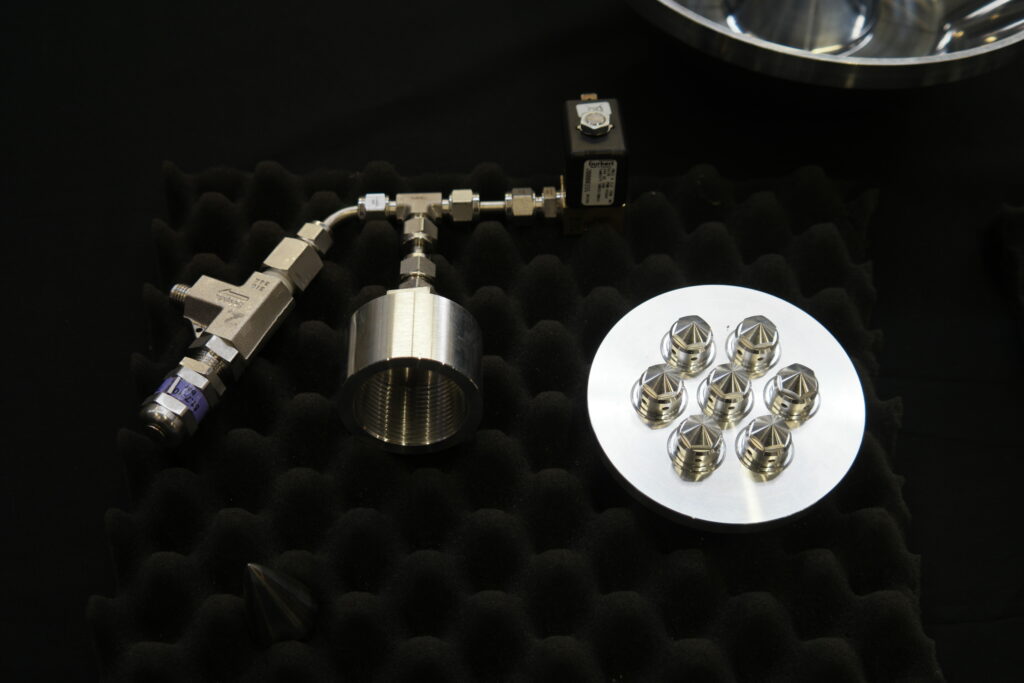

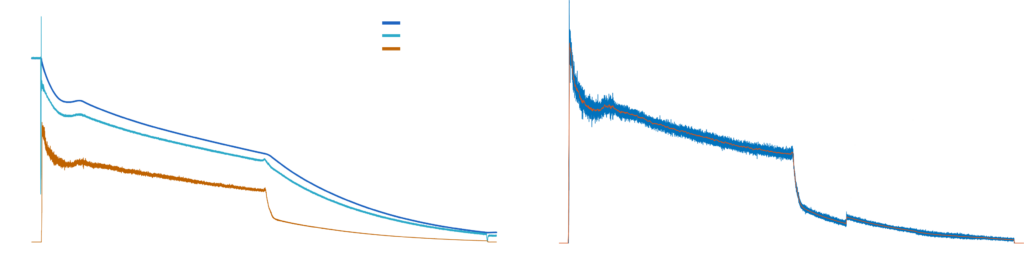

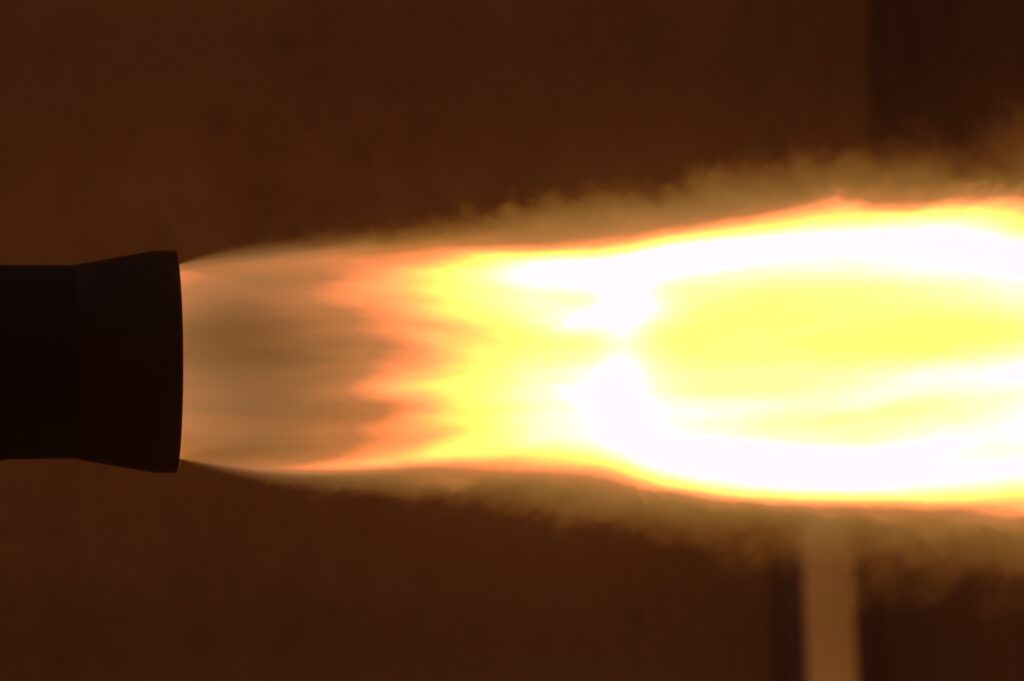

Propulsion is provided by the spare HyLIGHT hybrid engine from the first campaign, with thrust performance in the 15 kN class.

Propellant storability has been validated through long-term sample retention.

A new thrust connection was manually machined, where improved cutout shapes were implemented and verified in simulations, reducing structural mass by 400 g.

Fluid System

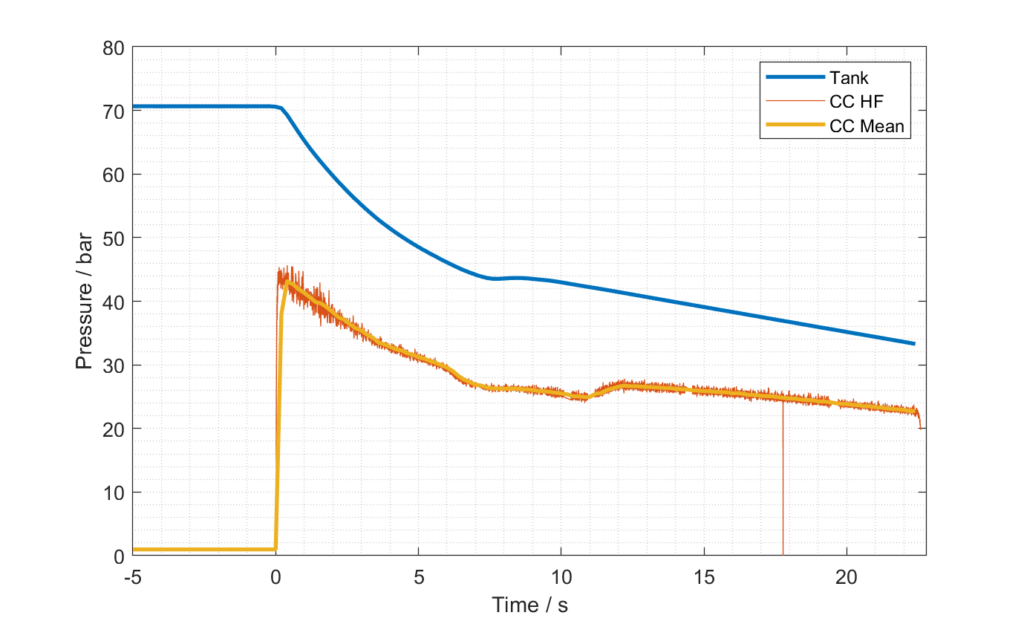

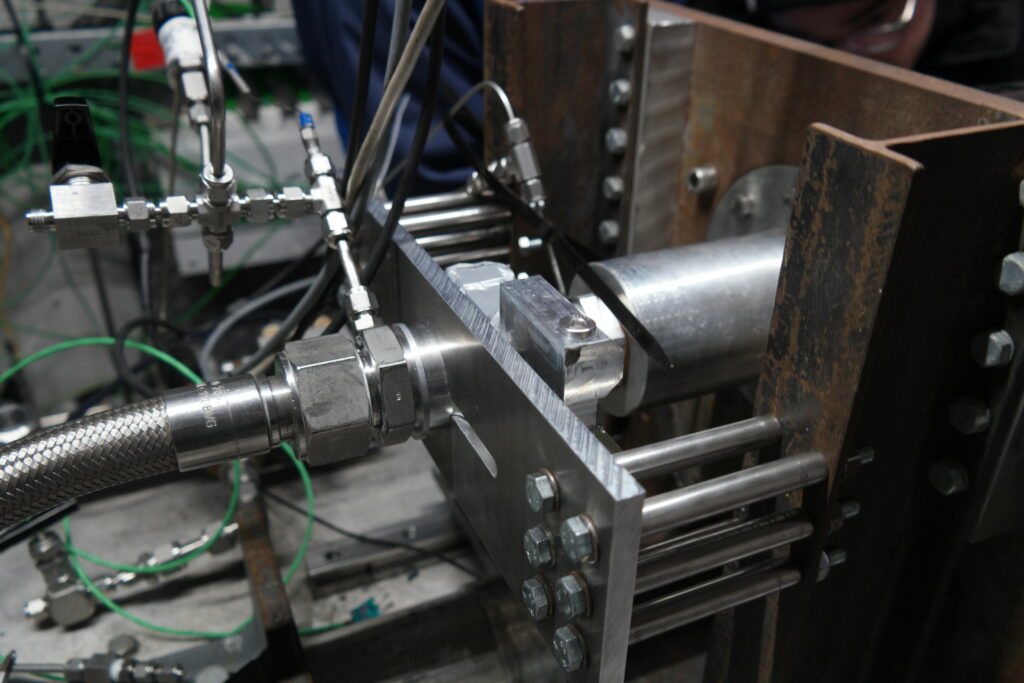

The main valve remains unchanged and uses the spare from the first campaign, after a series of verification tests. The vent valve has been replaced with a solenoid valve.

Ground Support Equipment (GSE)

The GSE was completely redesigned for Project BLAST. The team conducted the design with compatibility for N2ORTH fueling built in, enabling the same proven loading procedure used in earlier flights.

Overview

| Total length | 7 m |

| Dry mass | 79 kg |

| Mission target | >100 km altitude |

| Objective | Become the first European student team to reach space, and the first worldwide to do so using a hybrid rocket! |

The vehicle is nearing completion and will be fully presented before launch. Launch opportunities and possible locations for 2026 are currently under evaluation.

To stay up to date with the upcoming N2ORTH-3 campaign and our other projects, follow our social media!