Project Update

Project Update

Launch Campaign Announcement

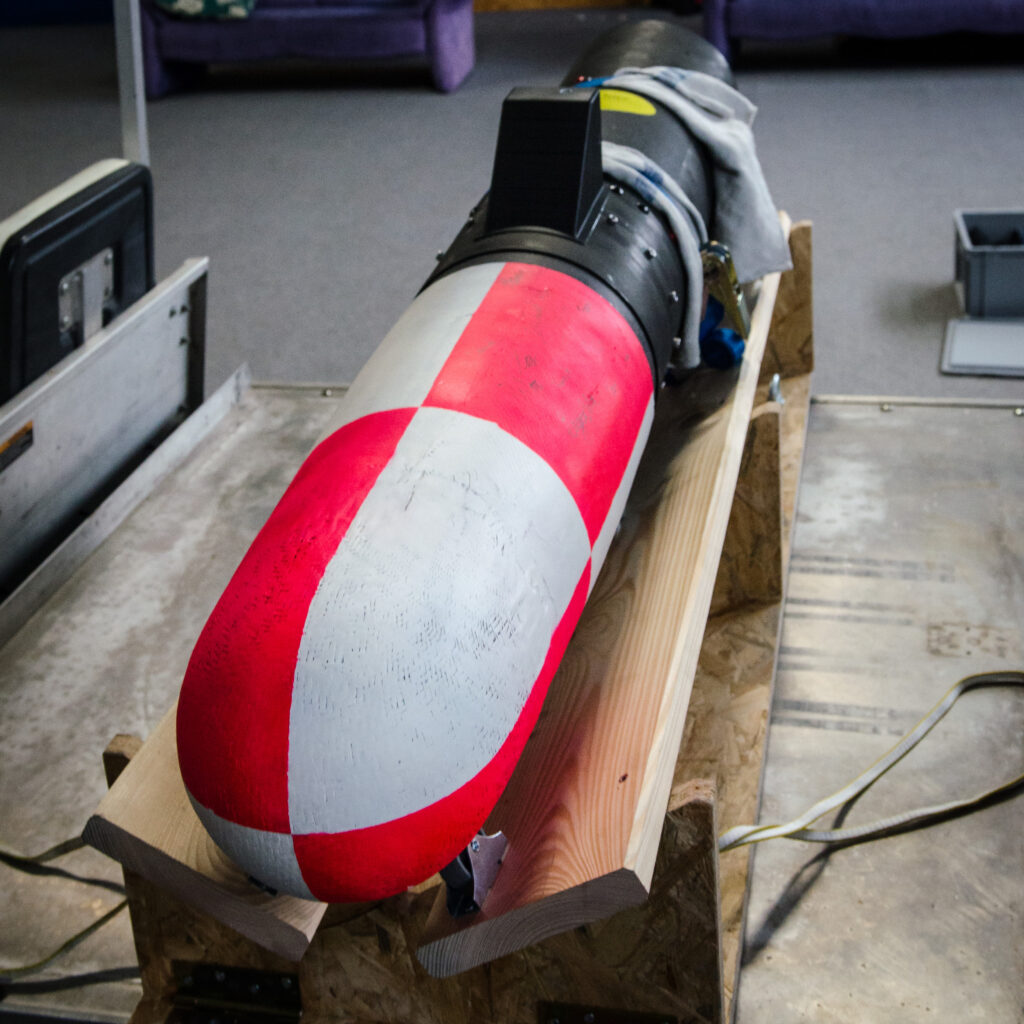

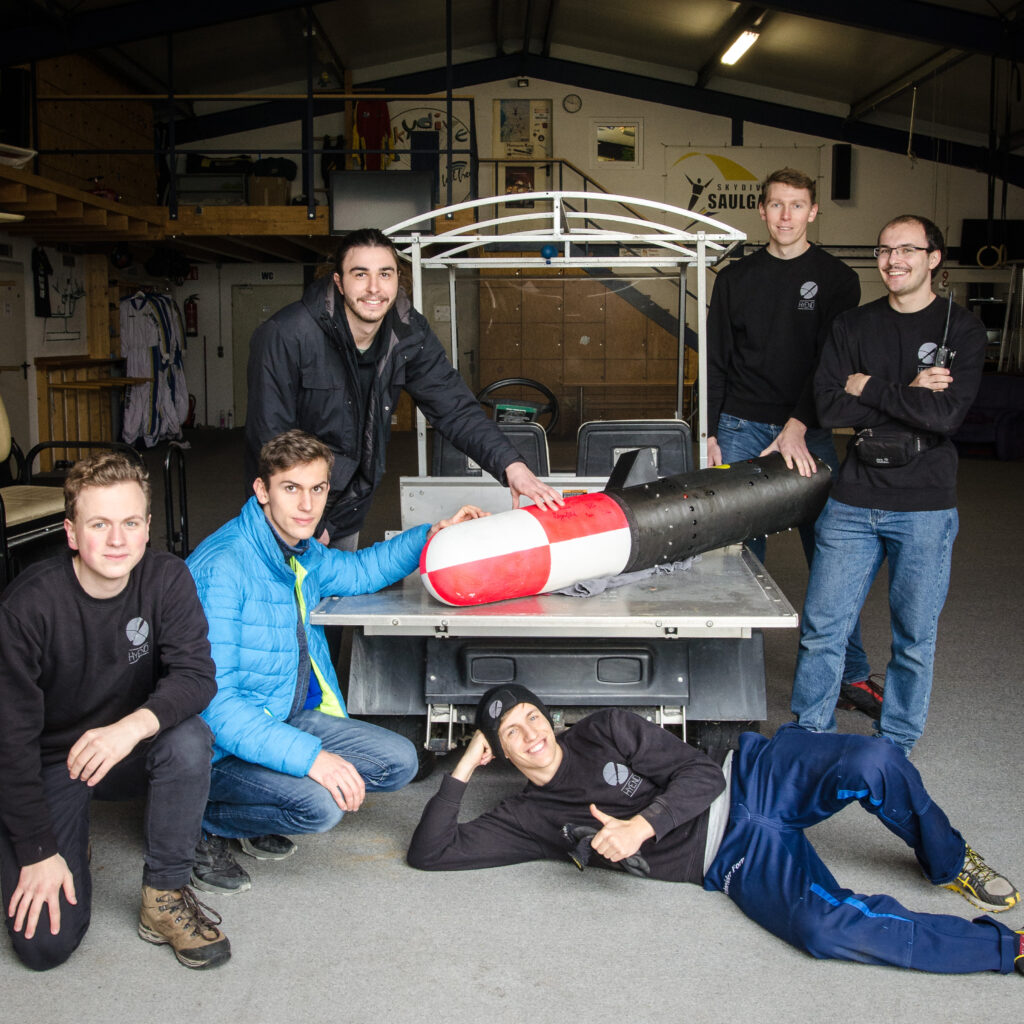

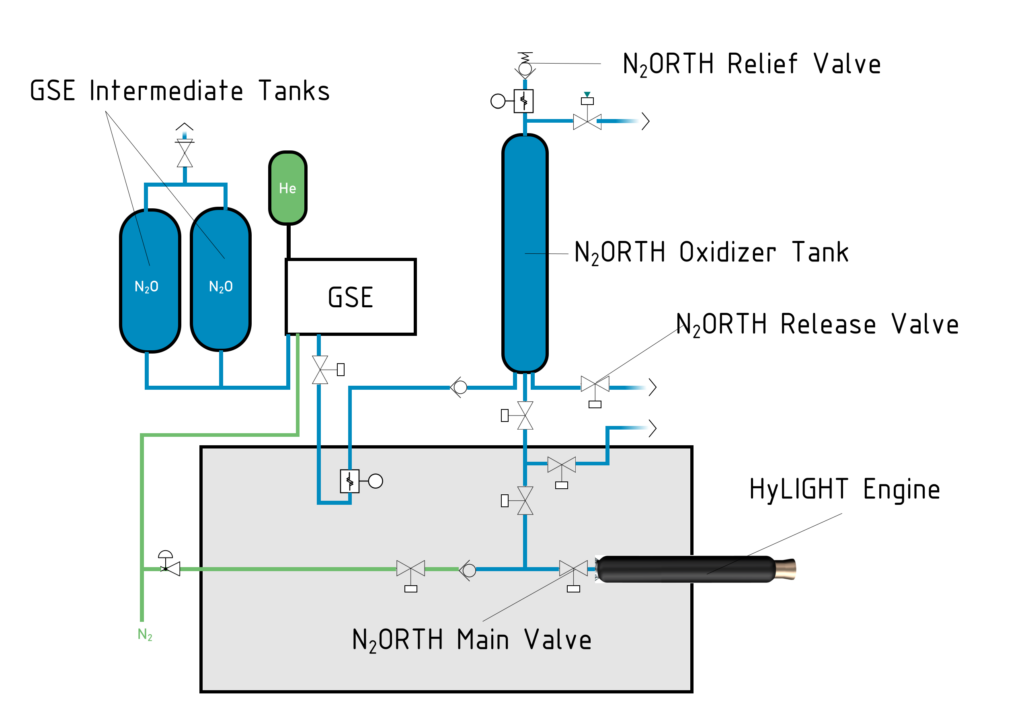

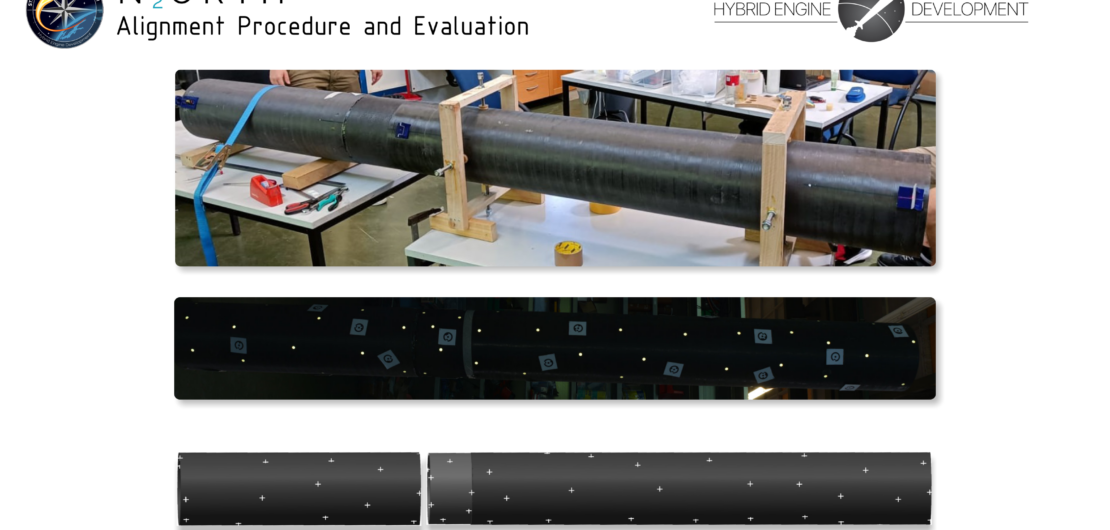

We are proud to announce the date of our launch campaign! From 11th to 25th April this year, 16 HyEnD team members will visit the European Space and Sounding Rocket Range (Esrange) close to Kiruna, Sweden. And we plan to not bring one – but two N2ORTH rockets with us!

The launch of the first N2ORTH rocket is planned with 80° of elevation and with limited propellant mass, in order to ensure a safe downrange and landing area. If all goes according to plan, N2ORTH will reach an altitude of more than 50 km at its first flight and we will get the permission to increase the elevation for the second rocket launch. The launch of the second N2ORTH rocket is currently planned with a higher elevation and increased propellant mass.

As of now, a space shot is not off the table but will also depend on the results of the first launch and weather conditions. We are looking forward to share more details about the launch campaign in the upcoming weeks.